The Role of Carbon Graphite Yarn Packing in Sealing Solutions

In the world of industrial equipment, ensuring that pumps, valves, and other components are sealed effectively is crucial. One of the unsung heroes in this

Home » Blog

In the world of industrial equipment, ensuring that pumps, valves, and other components are sealed effectively is crucial. One of the unsung heroes in this

The chemical industry operates in environments where safety and reliability are paramount. From corrosive chemicals to extreme temperatures and pressures, the conditions in chemical processing

The aerospace industry demands maximum precision, reliability, and safety. In this context, mechanical seals play an important role in maintaining the integrity and performance of

In industrial settings where steam generation is crucial, maintaining efficient and safe boiler operations is paramount. One critical component that ensures the smooth functioning of

In the high-stakes world of aerospace, where precision, efficiency, and reliability are non-negotiable, mechanical seals play an indispensable role. These sophisticated devices are engineered to

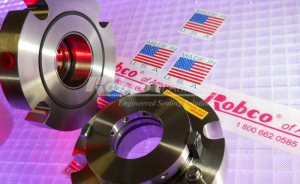

In the realm of industrial applications, the efficiency and reliability of machinery hinge significantly on the quality of the seals used. At Robco of America,

Robco of America, since 1923, has provided excellent alternatives to OEM products along with reliable Fluid Sealing Solutions to U.S.

Toll Free: 800-662-0585

North East: 203-661-3284

Copyright © 2024 Robco of America | Company