MECHANICAL SEAL DESIGN & REPAIR FOR THE REFRIGERATION & COLD STORAGE INDUSTRY

Home » Refrigeration & Cold Storage

Quick service on seal repair or new pump seal.

- Operational safety

- Emissions

- Ammonia pumps

- Brine pumps

- Seal face combinations

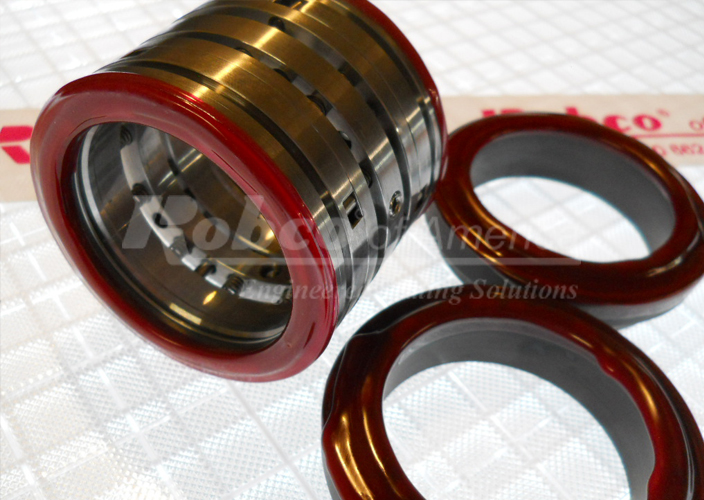

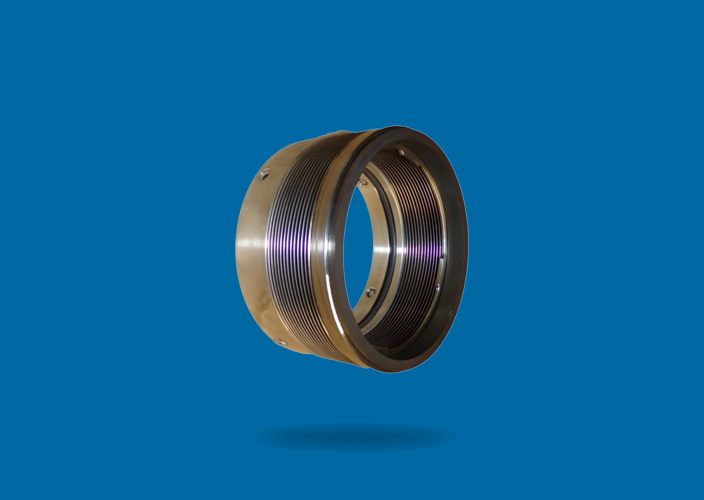

This Mycom 160 double seal set was sent in from a plant in San Antonio, Texas. The rotary double seal assembly had been slipping on the rotary shaft because the setscrews backed off. The I.D. bore of the rotary seal housing was scored up and the o’rings were burnt up. The two stationary Carbon seats were chipped out and needed replacing. We machined two new stationary Carbon seats in house and relapped the two rotary Tungsten Carbide seal faces. Rotary seal housing was re-machined and polished in I.D. o’ring grooves to remove wear. New springs installed with new Viton o’rings. Seal was repaired under emergency basis 24 hr. turnaround.

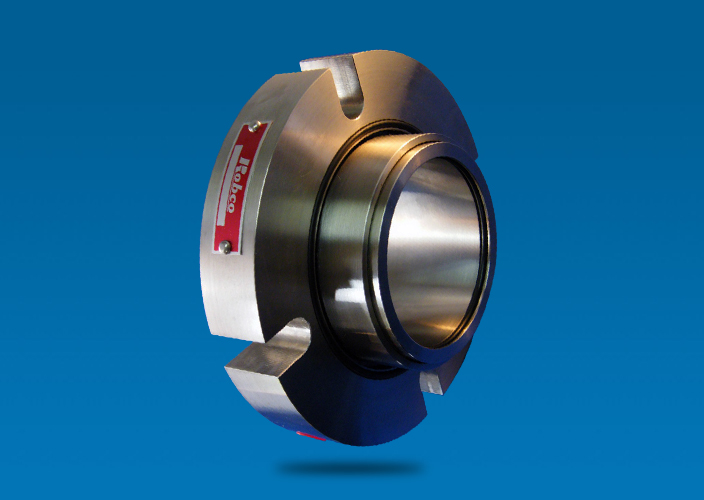

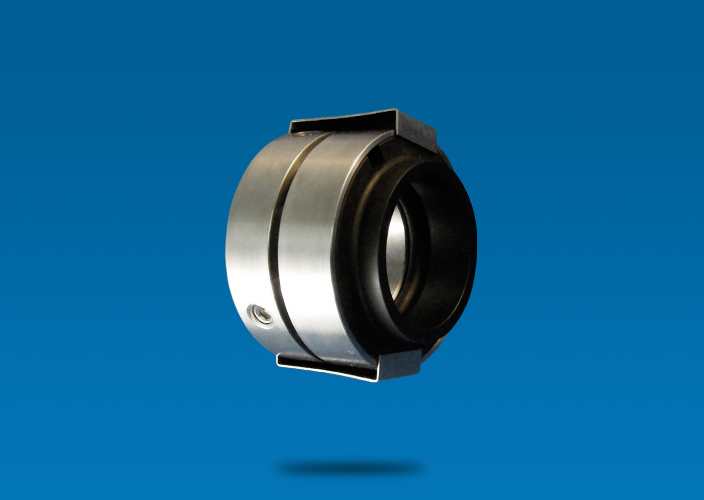

Frick 233 seal assy. sent in from a plant in Mexico. This seal has the normal wear seen on Frick seals. A chipped out & worn stationary Carbon seal face. A new Carbon seal face was machined in house. The rotary steel seat was re-machined, polished and relapped flat within 2 Helium light bands.

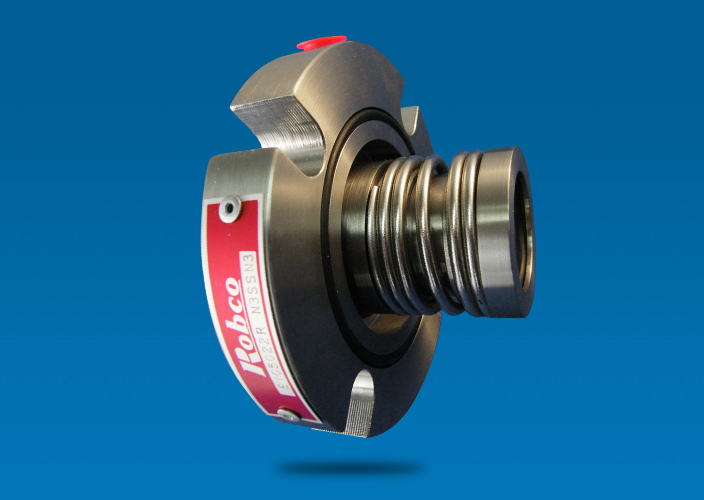

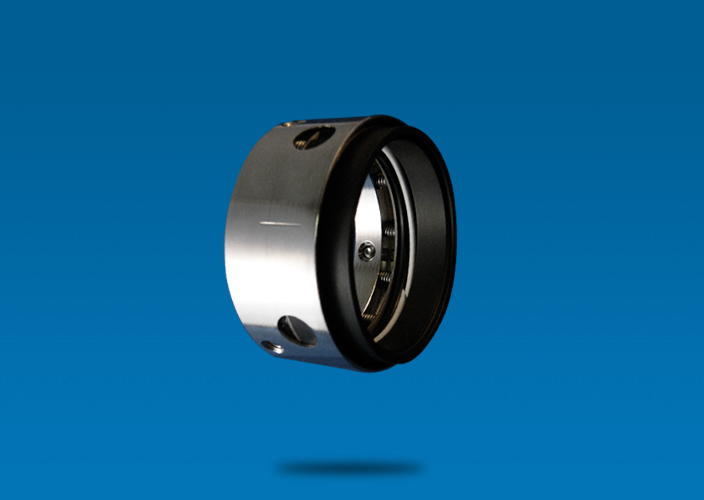

Howden 255 MK IV seal set sent in from Illinois. This seal had extensive wear on both the rotary Carbon seal face and stationary steel seat. We machined a new Carbon seal face in house and re-machined the steel seat. Both faces relapped flat within 2 Helium light bands. Repair carried out within 24 hrs.

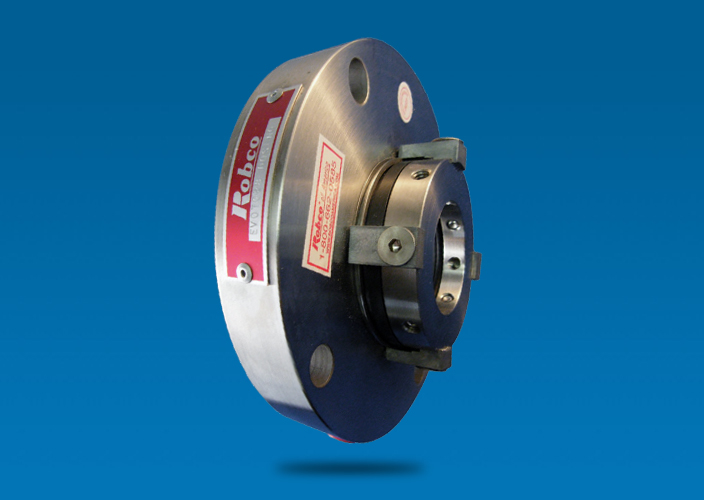

Frick 355 & 100MM FES-GEA seal sets sent in for repair from Industrial Refrigeration plant in Alaska. New Carbon seal face machined and rotary seat re-lapped flat, o’ring sealing surfaces polished. Seals were repaired in 2 days under emergency basis.

Mechanical Seals

E01

EV03

EV05

EV07

R2

R6

R8 & R9

Custom Design, Engineering Services & Repair

Custom Designed Seals

Custom Engineering

Reactor, Agitator and Mixer Repair

Other Products