NETZSCH DOUBLE BEADMILL SEAL REPAIR

Home » CASE STUDIES » Netzsch Double Beadmill Seal Repair

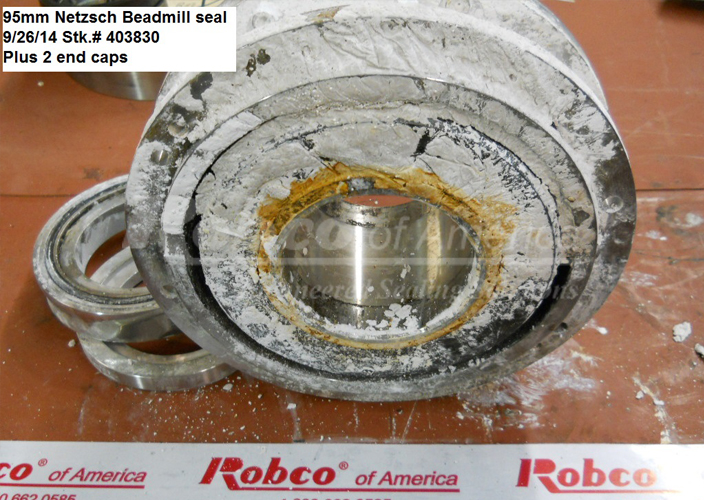

95mm Netzsch double beadmillsent in for failure analysis and overhaul.

This mechanical bead mill seal was sent to our Houston, Texas repair facility after being in operation for 6 months. The seal was in poor condition due to the product side WEAR PLATE wearing down and allowing the abrasive product to get to the inner portions of the seal clogging the springs which caused seal failure.

Emergency Repair

95mm Netzsch double beadmill seal sent in for failure analysis and overhaul.

This mechanical seal was sent to our Houston, Texas repair facility after being in operation for 6 months. The seal was in poor condition due to the product side WEAR PLATE wearing down and allowing the abrasive product to get to the inner portions of the seal clogging the springs which caused seal failure.

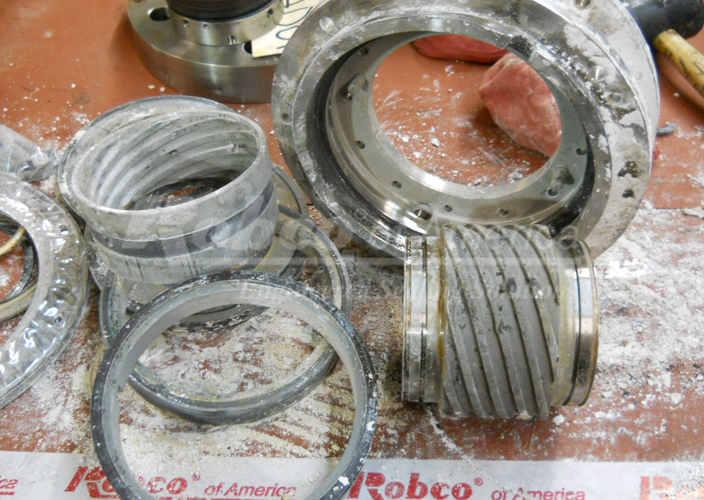

Robco advised customer to upgrade the inner seal wear plate to solid TUNGSTEN from the case hardened STEEL plate. Also upgrade the inner seal faces to solid TUNGSTEN from the existing metal rotary seat and stationary face.

All other seal parts required extensive re-machining and polishing on o’ring sealing surfaces. BEADMILL seal was turned around in 5 working days on an emergency basis due to plant going to shutdown mode due to seal failure.

Work Rendered for Repair