Custom engineered critical components to increase MTBF (mean time between failure) of your PUMPS, MIXERS,DRYERS, AGITATORS & BEADMILLS.

We can recommend upgrades in materials of construction utilizing advanced grades of SILICON CARBIDE, TUNGSTEN CARBIDE, METALLIZED CARBON, GRAPHITE IMPREGNATED CARBON & GLASS FILLED PTFE. These upgrades will extend the operating limits of your rotating equipment.

Custom Engineered Work

This VONK CHOKE VALVE was sent in from a chemical plant in Louisiana. End user informed us that this model VONK CHOKE VALVE had a 10 week delivery for a new one. We informed the customer that we could repair the valve by cutting out the worn section and reverse engineer the internal parameters. A new valve neck and flange was machined as a one piece unit. We designed and fabricated an internal plug that would allow for the new section to be welded in place in such a way that all internal clearances were an exact match to how the valve would be in new condition. We also installed a new SILICON CARBIDE internal wear bushing. The VONK CHOKE VALVE was repaired in 3 working days.

Custom designed Ball Valve components. Tungsten seat has custom designed sealing surface to produce a longer lasting seal. Ball is Rexalloy. This material combination is producing run cycles double the original components. Installed in chemical plant in Pasadena, Texas.

6 inch long Carbon Graphite pump shaft bushings made for Houston water authority pump overhaul.

New rubber coated wear plate fabricated and installed on Netzsch Beadmill Mechanical Seal.

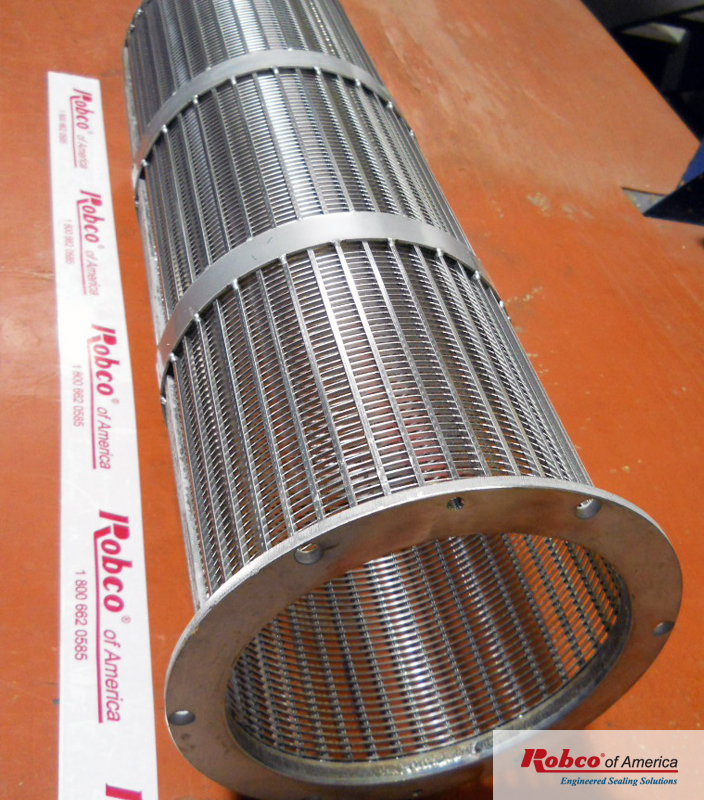

12″ dia. by 24″ lg. Wedge Wire Strainer Basket redesigned to handle high rotational torque application.

Agitator shaft lower bushing assembly with Graphite bearing sleeve press fitted.

3.00″ Chrome Oxide coated shaft sleeve with 2 o’rings on I.D. & setscrew drive.

Spare parts kit for Auto clean power strainer unit in chemical plant.

Rubber coated wear plate sent in to Robco for repair.

7″ Metallized Carbon bearing for Ingersoll Rand 16″ VEM boiler circulating pump.

Spring loaded clamp set.

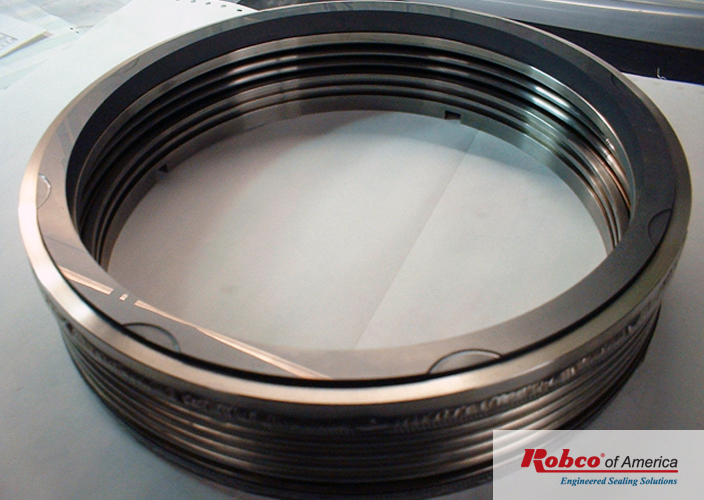

9″ Hydro Formed metal bellows seal with Silicon carbide insert scalloped to improve lubrication and decrease pressure loading of rotary seal during operation.

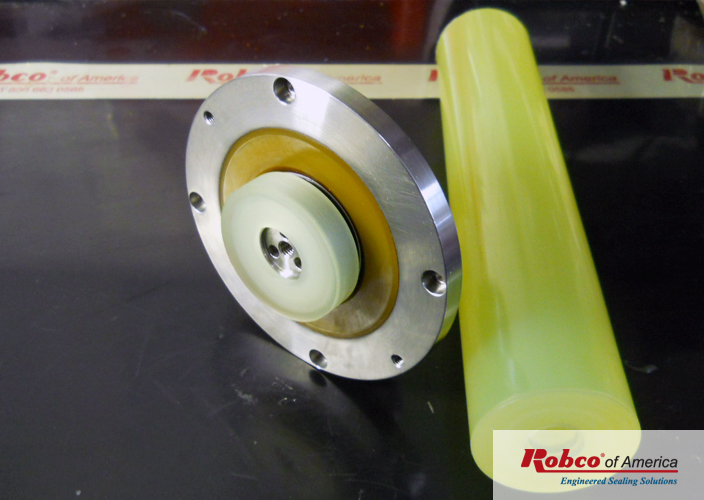

24MM double Mixer Seal modified to incorporatean abrasive resistant cover machined from Polyurethane.

Clamp Set with EDM cut “V” grooves

Contact Robco of America right now if you need emergency mechanical seal repair. We provide quick response service.