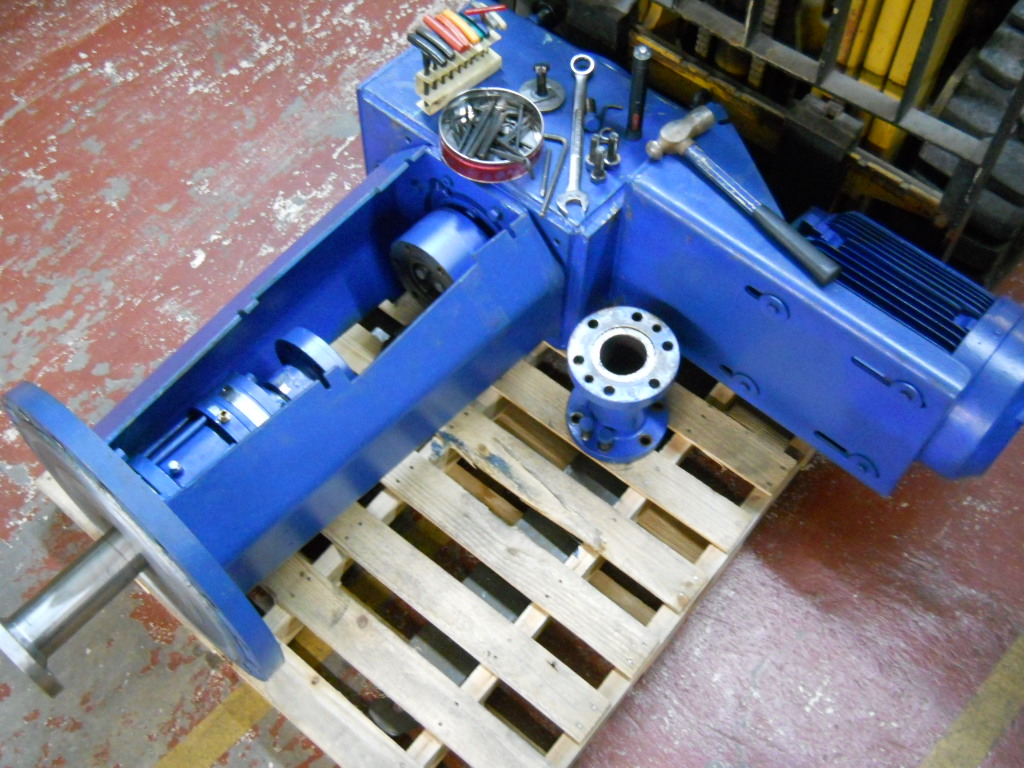

A tire sealant manufacturing company in Texas sent this Lightnin mixer unit

in for overhaul. The GEARBOX was leaking oil into the mixing tank

contaminating the batch production. Upon inspection we found the

BEARINGS had failed causing the LIP SEALS to fail. All new bearings & lip

seals installed, o’rings replaced and the rotary shaft was polished on the

lip seal surfaces.

An adhesive manufacturer in Houston, Texas sent this Viking K8124A

magnetic pump in for overhaul. It had seized up. All bearings, lip seals and

o’rings were replaced. Pump was re-assembled and pressure tested to

60 PSIG.

A chemical plant in New Mexico sent this 120mm Nippon Pillar seal into our

Texas repair facility for overhaul. Seal had Tungsten Carbide vs Tungsten

Carbide on inboard end and Carbon Graphite vs Tungsten Carbide on outer

end. The outer stationary Carbon Graphite seal face was chipped out and

cracked. The (3) Tungsten faces required clean up & relap flat within

2 Helium light bands. We machined a new Carbon Graphite seal face

in house. All the metal parts required clean up & polish on o’ring sealing

surfaces. One of the wavesprings was damaged and required replacing.

Robco of America had a new wavespring manufactured to our specifications

to supply adequate seal face pressure. Seal was re-assembled & passed

our 60 PSIG pressure test. Seal is back in operation.

A chemical batch processing plant in Oklahoma sent this 110mm Burgmann

double mixer seal in to our Texas repair facility for inspection & overhaul.

Upon inspection we found the two rotary Carbon Graphite seal faces were

worn and the two stationary Silicon Carbide seats were chipped & cracked.

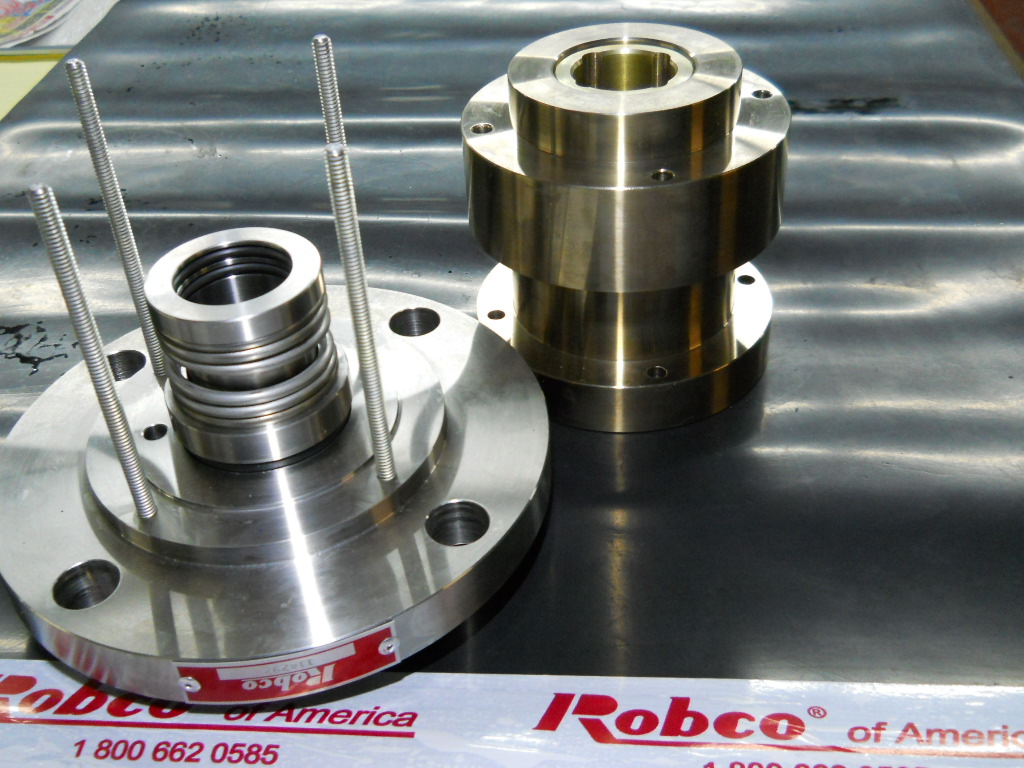

A pump repair company in Illinois sent these two 3.00″ Cartridge seals in

to our repair facility for emergency overhaul. They had Carbon stationary

seal faces running against rotary Silicon Carbide seats. They had wave

springs behind the stationary Carbon seal faces and Viton o’rings. The

Carbon seal faces were severely worn and required replacement. We

machined new Carbon seal faces in house. The Silicon Carbide seats

were re-ground & lapped flat within 2 helium light bands. New wavesprings,

Viton o’rings, setscrews, setsclips and drive pins installed. All metal parts

were re-machined and polished on o’ring sealing surfaces. These seals

were re-assembled and pressure tested to 60 psig for 10 min. with no

loss of pressure. Repair job was turned around in two working days

due to customer losing production.

A company in Italy contacted Robco of America in regards to designing &

manufacturing some Silicon Carbide wearplates for an industrial centrifuge

application. Customer wanted a Hastalloy outer band press fitted onto the

wearplates. We were able to turn the job around in 2 weeks due to

customer deadline.

A chemical plant in Louisiana sent a 2.00″ Chemineer (model HTN) double

mixer seal in for failure analysis and repair. Upon inspection we found the

product side stationary Silicon Carbide seat had cracked and chipped out

causing the barrier fluid to leak into the mixing tank. Silicon Carbide seats

are prone to chipping out and cracking in the area where they engage an

anti rotation pin. We made the recommendation to change out for a Tungsten

Carbide seat after confirming the product would not physically attack the

Tungsten material. Tungsten Carbide will not chip out or fracture due to pin

engagement. We machined new Carbon Graphite rotary seal faces and

swapped out the outboard end stationary Silicon seat for a Tungsten Carbide

seat. All o’ring sealing surfaces were polished and we installed a new bearing

and lip seals. The seal was re-assembled and pressure tested to 60psig for

15min. with no pressure drop. The Chemineer HTN seal has been back in

operation for 9 months.

A chemical plant in Alabama sent a 95mm Netzsch double Beadmill seal in

for overhaul. It was in extremely poor condition. We had a new product side

wear plate made from solid Tungsten Carbide to replace the old Chrome

coated plate. Both rotary coated seats were replaced with solid Tungsten

Carbide seats. A new product side stationary Tungsten Carbide seal face

installed. On the outer end we machined a new Carbon Graphite stationary

seal face. A new rotary seal sleeve was made. The Netzsch double seal

uses two end caps that are installed around the Netzsch seal we replaced

both of them, machined from 316 Stainless. The seal was re-assembled

& pressure tested to 80 psig for 15 min, no pressure drop.

A pump company in Houston, Texas wanted a custom designed / manufactured

cartridge seal to install in a vertical pump for a municipal water district. They were

having issues with the original seals failing prematurely due to the pump shaft

steady bushings wearing out too quickly. We designed a cartridge seal that had a

heavy duty built in shaft steady bushing machined from a metallized carbon graphite

with built in internal channels to help increase fluid through around the bushing. This

seal has been running for 5 years , the original seals were failing after 4-6 months.

All the pumps in this municipal district have been overhauled and have the Robco

designed seals installed.

A company in the Middle East contacted Robco of America to see if we could fix

some issues with a set of Pratt & Whitney turbine bearing seal assemblies. End

user was having issues with the quality of work being carried out at a repair facility

in Europe. We designed custom lapping equipment to rework the Carbon seal rings

and meet the required tolerances. The turbine bearing seal assemblies were shipped

back to the Middle East and are now in operation. End user informed Robco of America

they will send all future assemblies to us for overhaul.

A company in the Middle East contacted Robco of America to see if we could fix

some issues with a set of Pratt & Whitney turbine bearing seal assemblies. End

user was having issues with the quality of work being carried out at a repair facility

in Europe. We designed custom lapping equipment to rework the Carbon seal rings

and meet the required tolerances. The turbine bearing seal assemblies were shipped

back to the Middle East and are now in operation. End user informed Robco of America

they will send all future assemblies to us for overhaul.

Chemical processing plant in Puerto Rico sent this 95mm double reactor seal with lower

glass lined flange in for overhaul. It has Kalrez o’rings for the high operating temps.

(440 deg. F.) Tungsten Carbide vs Silicon Carbide on product side. Carbon Graphite vs

Tungsten on outer end. Reason for seal failure was the worn lower shaft steady bushing

in the bottom of the 20,000 Gal. tank. This allowed the shaft to rotate outside of allowable

radial tolerances. We replaced the seal faces and seats. Machined a new double walled

seal housing which allows for the addition of cooling fluids to control temps. in the seal,

installed new Kalrez o’rings. Mechanical Seal was re-assembled and pressure tested to 80psig for

15 min, no pressure drop.

80mm Netzsch Double Mill Seal sent in for overhaul from chemical plant in Kentucky.

This unit had Silicon Carbide vs Silicon Carbide on both the product side and the outer end.

The Silicon Carbide seal faces & seats were chipped / cracked around the drive pin slots.

We advised the customer to upgrade material of construction to Tungsten Carbide which

is less prone to chipping / cracking. The end user agreed and we had new seal faces and

seats manufactured. Seal was repaired and pressure tested to 80 PSIG. Unit is now

back in operation.

3.00″ Double Mixer Seal sent in for emergency repair from chemical plant

in Pasadena Texas. Rotary Silicon Carbide seal faces were worn & chipped out. Stationary

product end Silicon Carbide seat was worn and chipped.

Rotary seal sleeve was worn and pitted on o’ring sealing surfaces, new sleeve required.

This seal has Kalrez o’rings on product end due to elevated operating temps. (+400F).

Robco of America had a repair kit on the shelf for this emergency overhaul. Seal was

turned around in (2) working days.

Chemical plant in North Carolina sent a failed 100mm Double Mixer Seal in for replacement.

We reverse engineered and provided a replacement mechanical seal unit. We upgraded the

product side seal faces to Tungsten vs Silicon from original Silicon vs Carbon. Seal has

been back in operation for 2 yrs.

3.75″ Robco EV05 single spring cartridge seals installed on (2) split case pumps ready

to transport to North Carolina.

1.75″ Robco seals being installed at airport fuel depot in Louisiana.

Thrust bearing & Pivot shoe set repaired & relapped flat within two Helium Light bands

for Deepwell Submersible Pump operating in Gulf of Mexico.

4.00″ Robco EV07 Double Cartridge Seal being installed on a Reactor unit at a

chemical plant in south Texas.