We have our own complete line of CARTRIDGE and ASSEMBLY style MECHANICAL SEALS DESIGNED and MANUFACTURED 100% in the USA to provide years of leak free service in all manner of sealing applications.

Our seals are designed with LARGER INTERNAL RADIAL CLEARANCES which translates into more reliable operation in equipment that may have MISALIGNMENT or VIBRATIONAL issues. We have LARGER RADIAL WALL THICKNESSES on our internal parts which translates into LESS DISTORTION due to PRESSURE or TEMPERATURE fluctuations. Robco of America DOES NOT provide a one seal fits all applications type of service. Our seals are tweaked and modified for each application which gives our customers a superior product and a superior solution.

Cartridge Mechanical Seals

Robco’s cartridge mechanical seals are designed to fit all ANSI pumps for ease of installation and are pressure tested at our Texas manufacturing facility prior to shipping. We can custom design any cartridge style seal to fit your most demanding applications. We use premium grade materials of construction throughout. All seals are made in the USA.

Assembly Seals

Robco of America offers a full selection of standard and custom designed assembly style seals. Our seals cover a broad range of demanding applications with our many options in materials of construction.

We can produce a reliable sealing solution for any application. Fast turnarounds are what we strive for to all our customers.

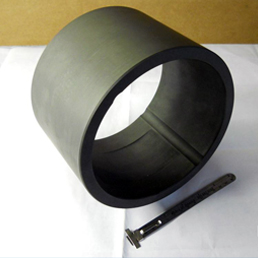

Seats

Robco of America stocks a broad selection of mechanical seals seats. Materials offered: Bronze,Carbon Graphite, Metallized carbon, Silicon carbide, Tungsten carbide, Ceramic, Stainless, Ni-Resist, !7-4 ph heat treated.

We can reverse engineer any worn seats & supply replacements in any of the above materials with fast turnarounds.

Bushings

Robco of America offers a broad range of restriction and steady bushings. We can reverse engineer worn shaft steady bushings and supply in an assortment of materials, including: Bronze, Metallized carbon, Carbon Graphite, Teflon, Tungsten Carbide, Silicon Carbide, Ceramic.

Contact Robco of America right now if you need emergency mechanical seal repair. We provide quick response service.