MECHANICAL SEAL REPAIR / REPLACEMENT FOR THE MARINE INDUSTRY

Home » Marine

We service the Marine Industry all along the Gulf Coast. Send your worn seals to our repair facility when your ship docks and we will provide FAST turnarounds with COMPETITIVE costs. We have extensive experience REPAIRING / REPLACING ALL MAKES / MODELS of mechanical seals.

Other Products

Gaskets

Mechanical Packing

Work for Marine Industry

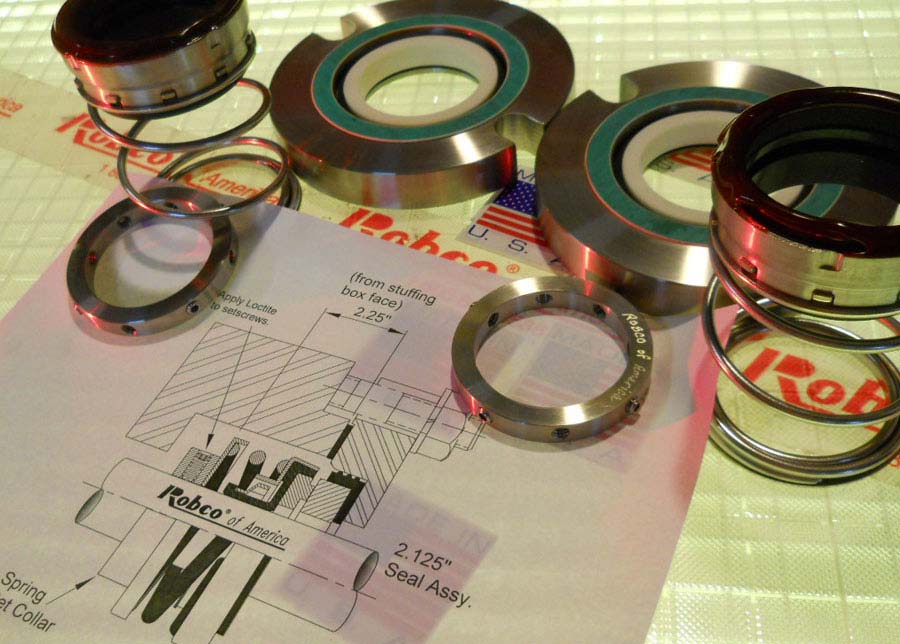

Seal assemblies built for Bilge Pumps.

Seal assemblies ready to be installed on chemical tanker transfer pumps.

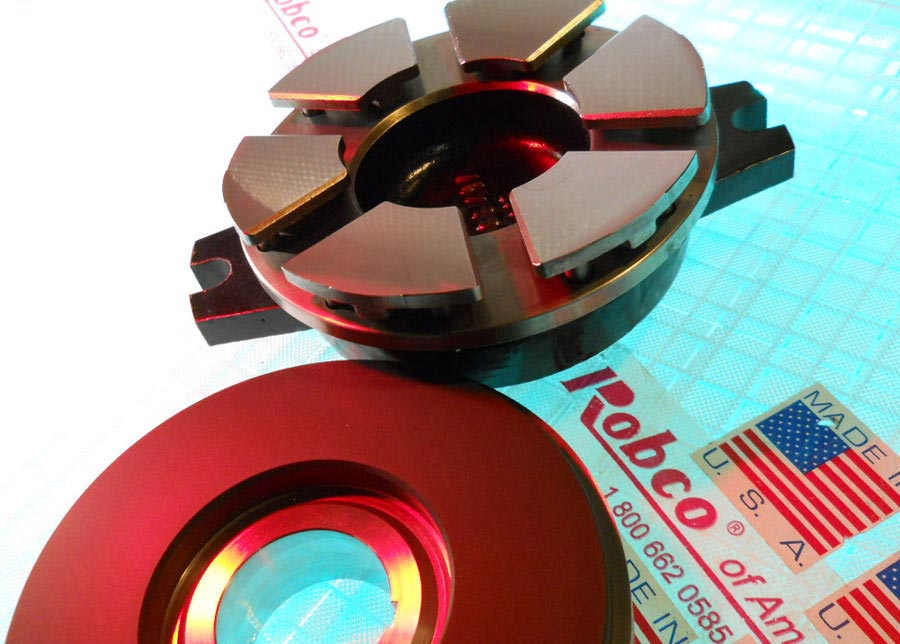

A seal set was sent in for repair. Seal was non repairable due to corrosion. Robco reverse engineered the stationary housing and upgraded materials of construction to mitigate corrosion.

Pivot Shoe & Thrust Pad set repaired for submersible pump. A new Carbon Graphite pad was machined, installed & lapped flat. Pivot shoe was cleaned & relapped flat.

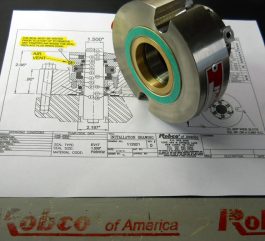

Robco designed / manufactured Metal Bellows Cartridge seals for sea water pumps on rigs in Gulf of Mexico.

Robco of America received (3) 85mm seals & (1) 100mm seal from a Chemical Tanker ship docked in the Port of Houston. All the rotary Chrome Oxide seal faces were cracked due to Thermal Expansion issues. All stationary Carbon seal seats were worn and cracked.

Metric mechanical seal sets for a Tanker Barge docked at Houston Port.

Marine Boiler Feed Pump seals being repaired.

Robco of America carried out an emergency basis repair. New rotary seal faces were machined from 17-4 PH Stainless and heat treated then lapped flat. New Carbon seats machined in house.

Job was turned around in 24 hrs due to Vessel leaving port next day.