TOLLING INDUSTRY - MECHANICAL SEALS / SHAFT STEADY BUSHINGS - NEW OR REPAIR

Home » Tolling

- All makes / models of seals repaired including but not limited to: Netzsch, Chemineer, Lightnin, Sharpe, Burgmann, Flowserve & Glass lined reactor seals

- We can upgrade materials of construction to increase seal run cycles

- Reverse engineer, replicate worn out mixer seals

- Custom design, manufacture seals for any application

- Repair / replace shaft steady bushing assemblies

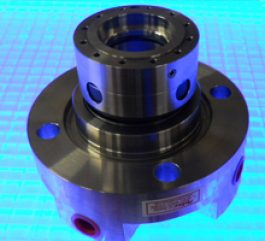

This is a 90mm Glass Lined double Reactor seal that was repaired and pressure tested. New Carbon Graphite seal faces machined and lapped flat within 2 Helium light bands. Silicon Carbide seats were replaced with Tungsten Carbide to overcome the problem of chipping and cracking.

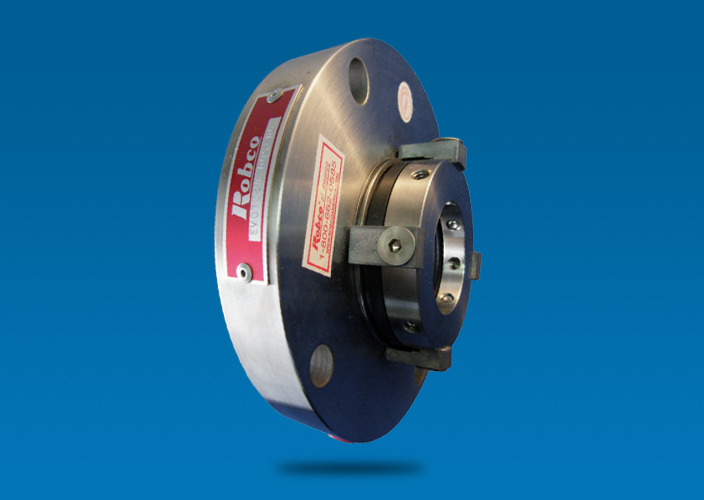

This is a 38mm seal assembly for use in a mixing tank in a Distillery. New Bronze seat was machined and lapped flat within 2 Helium light bands, new shaft steady bearing installed. New housing was machined from Stainless Steel to replace the old worn Aluminum housing.

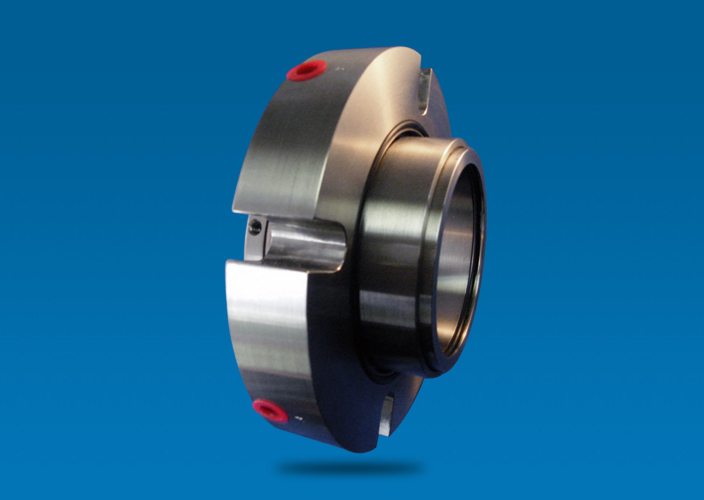

Two 50mm Chemineer agitator seals repaired. New Carbon Graphite seal faces machined and installed. Springs replaced and Silicon Carbide seats relapped flat within 2 Helium light bands.

This Lightnin Mixer unit was leaking from the internal bearing assembly. Oil was leaking into the mixing tank and contaminating the product batch. New bearings, grease seals installed. Shaft was re-machined and polished.

150mm Netzsch Beadmill seal repaired and pressure tested to 60 psig for 15 min. A new Epoxy wear plate was fabricated and new Silicon Carbide and Tungsten Carbide seal faces installed.

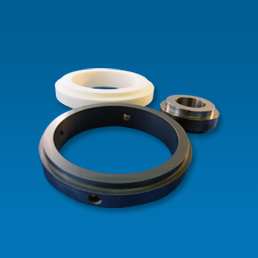

3" Shaft steady bushing assembly repaired. A new Glass Filled Teflon bushing was machined and shrink fitted into the tripod housing. A new Inconel rotary shaft sleeve was also machined.

2" Double Reactor seal assembly repaired. Machined new Carbon Graphite seal faces, new Silicon seats plus high temp. Kalrez o'rings and new shaft bearing installed.

Cartridge Seals

EV02

EV03

EV07

EV09

Custom Design Services

Custom Designed Seals

Other Products

Gaskets

Mechanical Packing