LIGHTNIN DOUBLE MIXER SEAL EMERGENCY REPAIR + NEW IMPELLOR SHAFT MACHINED

Home » CASE STUDIES » Lightnin Double Mixer Seal Emergency Repair + New Impellor Shaft Machined

Emergency Agitator Seal Repair

2.50″ Lightnin agitator seal assembly with old 7ft. long shaft & impeller assembly sent in for emergency repair.

Robco machined a new impeller shaft as well as a new Lightnin mechanical seal shaft due to poor condition. The Lightnin seal had new rotary & stationary Silicon Carbide & Tungsten seal faces installed. All metal sealing surfaces were re-machined & polished on o’ring sealing surfaces. A new lower shaft steady Bushing was fabricated using Carbon Graphite shrink fitted into original housing. Lightnin seal unit was re-assembled & pressure tested to 100 psig.

Complete turnaround on emergency job was 48 hrs.

Work Rendered for Emergency Repair

2.50″ Lightnin Agitator seal with 7ft / 2.50″ Dia. tank shaft & impeller sent in for repair.

All product side metal parts were badly corroded

2.50″ Lightnin agitator seal stripped down

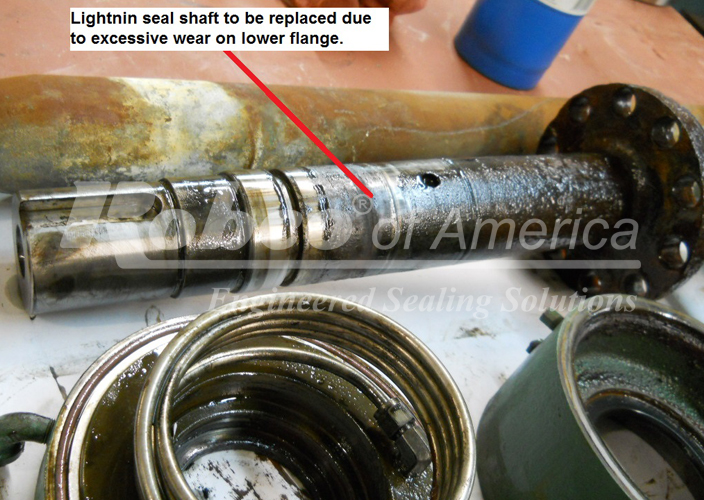

Lightnin seal shaft severely corroded on flange end

Impeller had broken / seized shaft in hub

New shaft machined for Lightnin seal

Lightnin seal repaired & pressure tested to 60 PSIG

Ready to ship out

New 2.50″ Dia. X 7ft tank shaft fabricated with impellor attached