GALLERY

Home » GALLERY

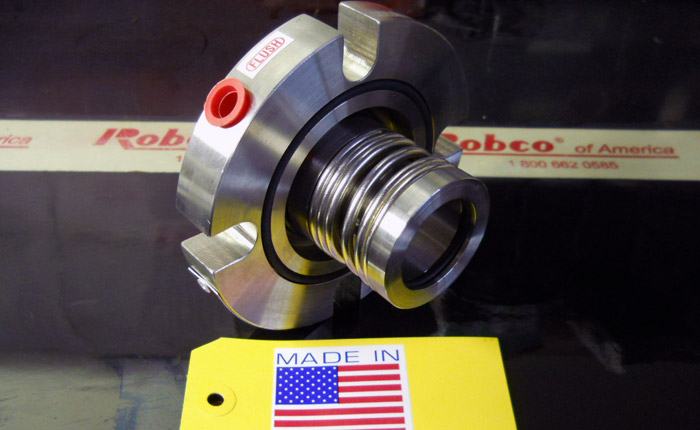

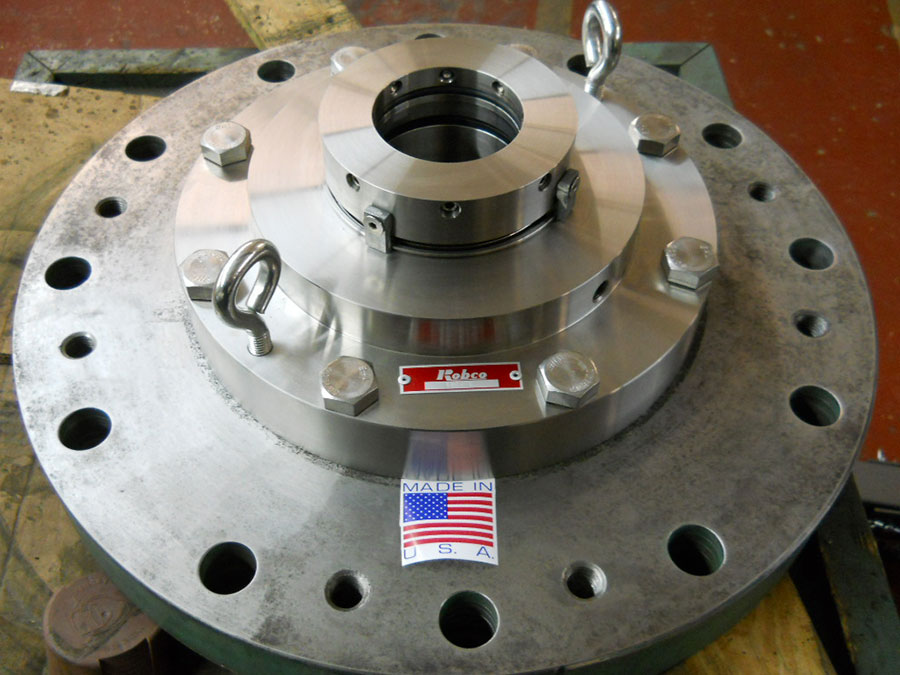

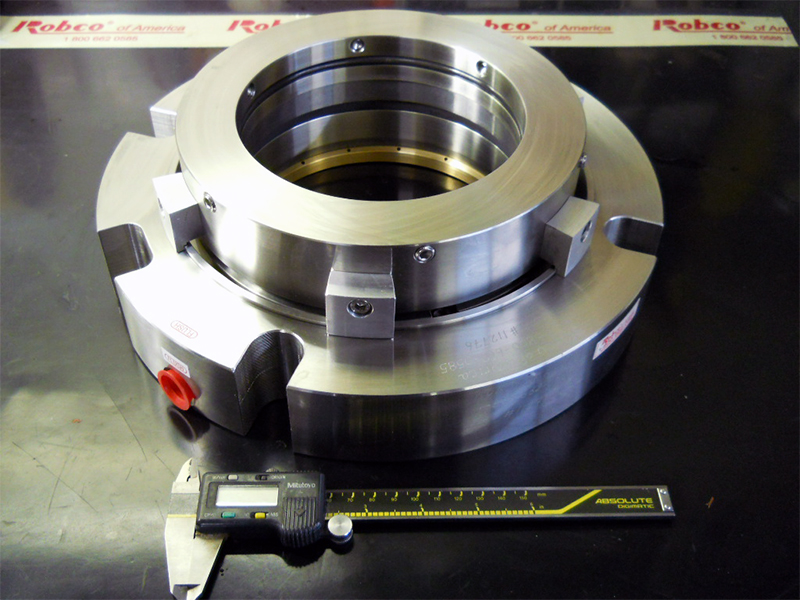

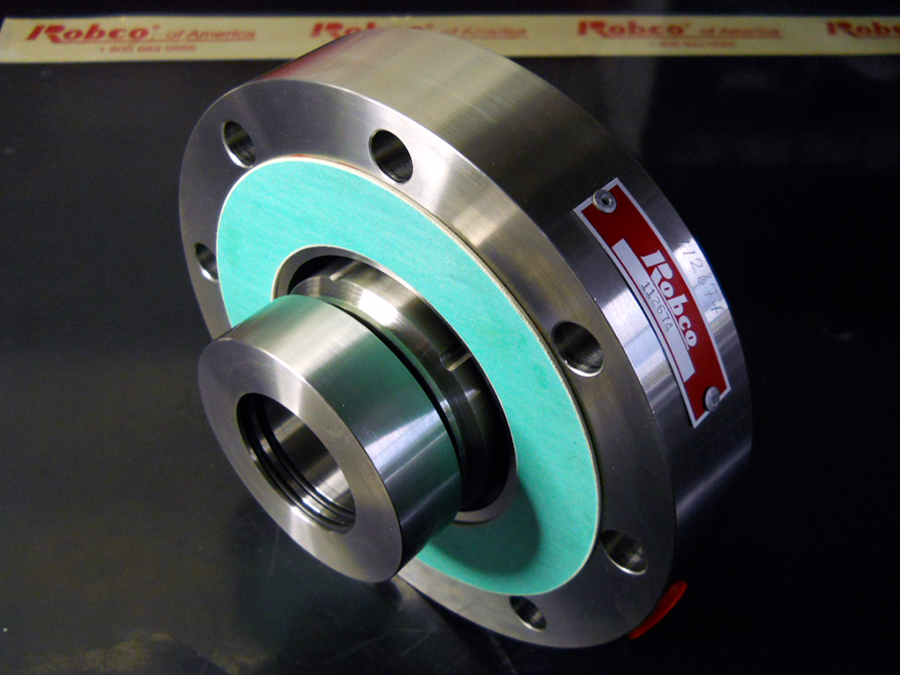

We manufacture our own complete line of Cartridge, Assembly style Mechanical Seals for Industrial Pumps, Compressors, Mixers, Agitators, Reactors and Beadmill units.

Robco can provide emergency repair/engineering serivces and a fast turnaround 24 hours / day, 7 days / week.

Collection of FRICK and MYCOM INDUSTRIAL REFRIGERATION COMPRESSOR SEALS repaired by Robco of America. Protective WAX applied to the LAPPED seal faces & seats.

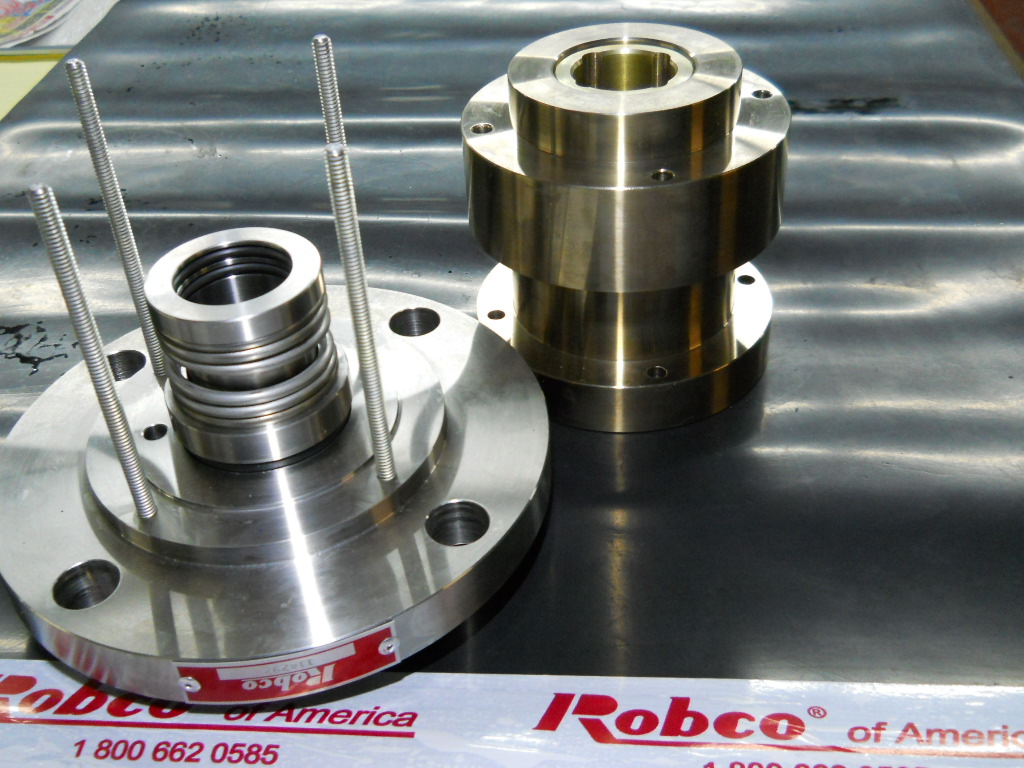

These are two CUSTOM DESIGNED assembly seals for a HORIZONTAL MIXER. The mixer handles Rubber compounds with Toluene, MEK, DMF, Ethyl Acetate & Ethyl Alcohol additives.

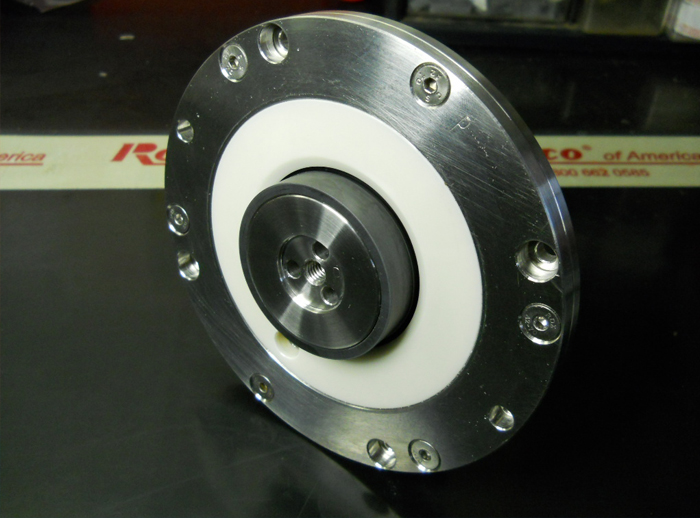

Robco of America DESIGNED & had these SILICON CARBIDE WEARPLATES manufactured to be installed into HIGH RPM CENTRIFUGAL ATOMIZER units. The wear plates are SHRINK FITTED into outer HASTALLOY C276 rings.

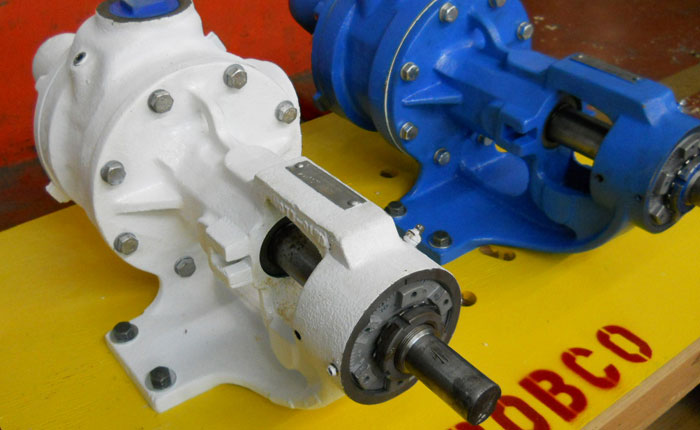

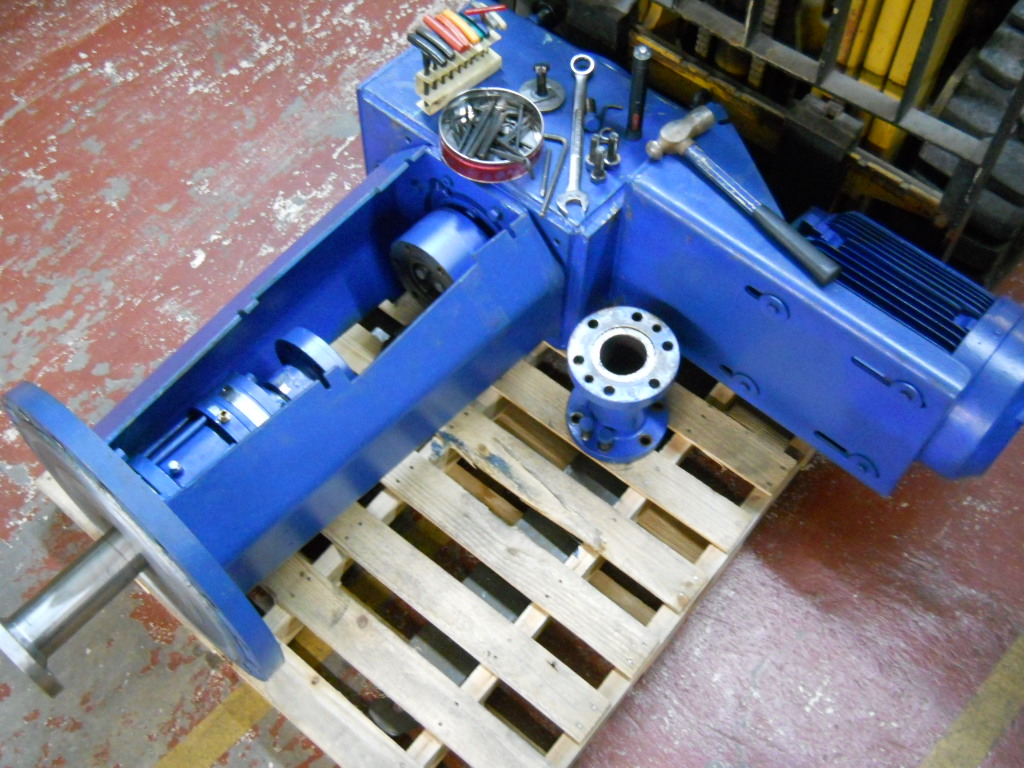

These two VIKING PUMPS (KK4125) were sent into our Houston repair facility for overhaul from an ADHESIVES MANUFACTURER in Texas. The mechanical seals were upgraded to handle the ELEVATED OPERATING TEMPS. Both pumps were overhauled and pressure tested to 80 PSIG for 15 min. with no pressure drop.

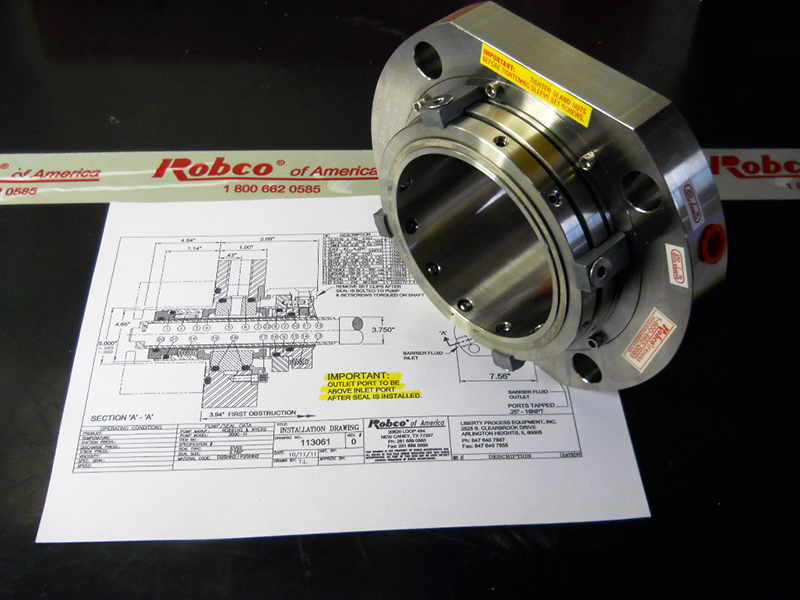

These are 3.50″ Robco EV05 custom designed cartridge seals for a splitcase pump in a water district pumping station.

This is a 100mm Pillar double cartridge seal. We installed new Silicon Carbide & Tungsten Carbide faces and machined a new outer end Carbon Graphite seal face. Chrome Oxide coated seat was relapped flat.

A chemical plant in East Texas sent two Chemineer agitator seal units in to our Houston, Texas facility for repair. The seals were in extremely poor condition with a lot of corrosion and wear. Both seals required new seal sleeves and double walled cooling jackets machined. Product side rotary seal faces were upgraded from Carbon to Tungsten Carbide to handle the abrasive elements in the mixed product.

The two stationary seats in each unit had been “slipping” in their housings causing wear on the o’ring sealing surfaces. This was due to the OEM seals not having anti-rotation pins installed to stop this from happening. We modified the stationary seat housings to stop this from being a future issue. These two seal units were repaired in 5 working days due to customer losing production.

This is a set of (24) nozzles comprising of a tapered Silicon Carbide insert that engages into a Hastalloy “C” housing with a tapered I.D. bore. These nozzles are installed in a 12,000 rpm centrifuge application in a chemical plant in Arkansas.

This is a custom designed Wedgewire strainer basket we had fabricated for an auto strainer unit in a chemical plant in Pasadena Texas. It has extra bands welded around the O.D. to protect the basket from the high torsional loads applied to the basket when the cleaning program kicks in.

Custom designed / manufactured 25mm high temp. metal bellows seal assembly designed for a chemical plant in Pasadena Texas.

3.00″ Type 8 Balanced rotary seal for a high pressure / high temp. application. We machined and fitted a custom designed outer pumping ring to aid in heat dissipation during operation. Seal is running in a 450 deg. F environment.

This 24mm double mixer seal operates in a very abrasive application. End user wanted the seal repaired and have a Polyurethane sleeve machined to protect the product side rotary seal sleeve. Pic. shows the seal with the Polyurethane sleeve installed on the seal.

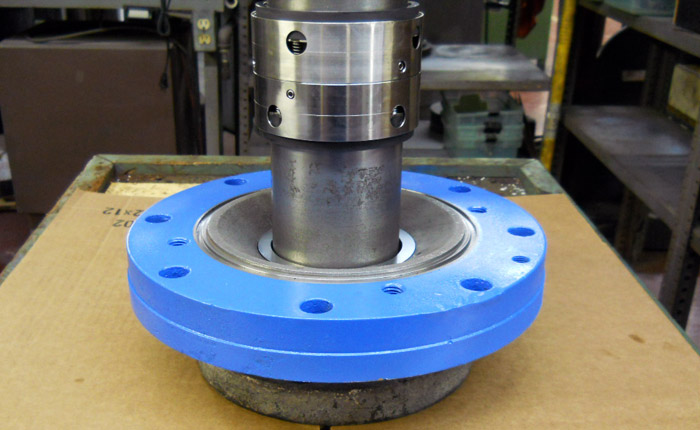

(2) 90mm custom designed / manufactured mechanical seals for a sewage treatment plant in Canada. The seals have hard seal faces – Tungsten Carbide vs Silicon Carbide to handle the abrasive media.

2.00″ Robco EV17 custom designed / manufactured Cartridge seals for vertical mixing tanks – Texas.

95mm Netzsch beadmill double seal repaired & pressure tested – Pasadena, Tx.

3.00″ Mixerpac double seal unit repaired & tested – Houston, Tx.

3.00″ Lightnin Mixer Seal converted from single to double seal being re-assembled – Pasadena, Tx.

80mm double Reactor seal repaired & pressure tested + new mounting flange – South Texas chemical plant.

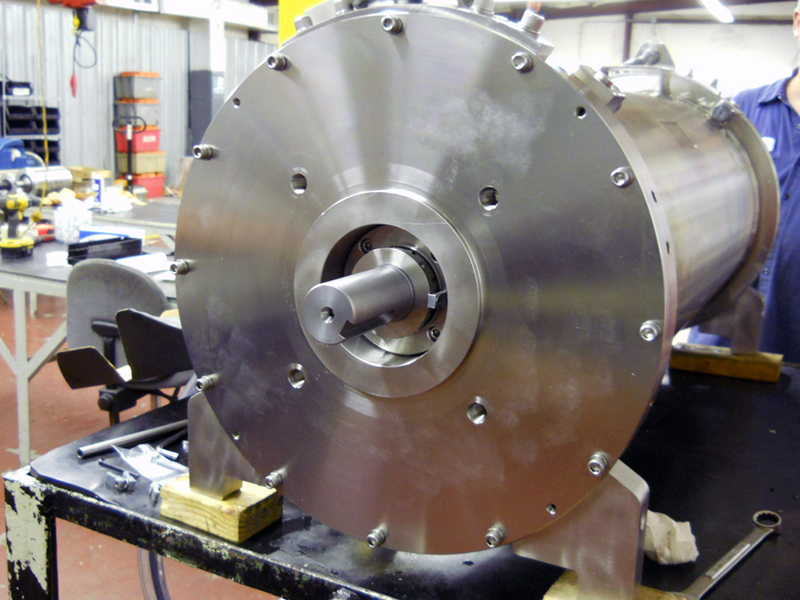

Custom designed / manufactured seal assemblies for industrial compressors – Louisiana.

Custom designed / manufactured Lip Seal for Centrifuge units – Louisiana.

60mm Rotary Union unit for beverage company – repaired & tested – South Carolina.

Pratt & Whitney double sided Carbon Seal Rings sent in for refurbishment – power plant in North Africa.

3.75″ EV03 double cartridge seal for Moyno Pump.

Convert from single to double seal unit.

EV05 single spring cartridge seal.

Type 8B high pressure.

3.25″ seal for Lightnin mixer unit.

3.00″ seal for 10,000 gal. mixing tank.

Ceramic lined double mixer seal.

Vertical mount mixer tank seal.

EV05

Sharpe mixer seal repaired and tested.

4″ EV17 on 12,000 gallon high pressure tank.

2.25″ EV17 on subsea ROV motor operating depth 1000m.

Custom seals for water and sewage industry.

2.00″ Robco EV06 Cartridge Seal.

Double mixer seal repaired & tested.

4.00” Lightnin seal unit repaired – before & after.