GLASS LINED DOUBLE REACTOR SEAL REPAIR

Home » CASE STUDIES » Glass Lined Double Reactor Seal Repair

Seal Repair

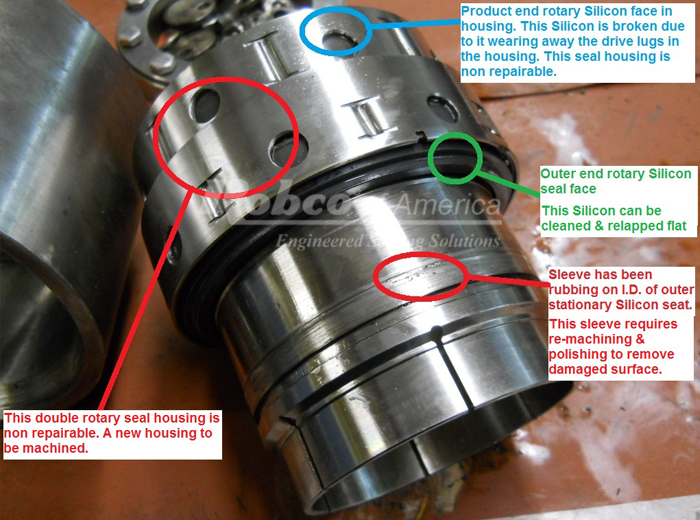

95mm glass lined double reactor seal sent in for repair from chemical plant in Texas. Unit had Silicon Carbide vs Silicon Carbide (inboard & outboard), Teflon encapsulated o’rings product side & Kalrez / Viton outboard. The product end rotary Silicon face was broken & jammed in the rotary housing. Upon inspection we found the drive lugs in the rotary metal holder were sheared off. A new Silicon face + 316 stainless holder required. The glass lined flange was cleaned up & painted. All metal parts cleaned, polished & re-machined as required. Mechanical Seal unit was reassembled & pressure tested to 100 psig. This job was turned around in 1 week.

Work Rendered for Reactor Seal

95mm Glass Lined double reactor seal sent in for repair.

Seal unit stripped down for inspection.

Rotary double seal unit with wear on sleeve & broken Silicon face.

Broken product end rotary Silicon face.

Seal parts repaired & ready for assembly.

95MM reactor seal assembled & pressure tested to 100 psig. Ready for delivery.