Vonk Choke Valve Overhaul

Home » CASE STUDIES » Vonk Choke Valve Overhaul

Vonk Choke Valve Sent in for Overhaul

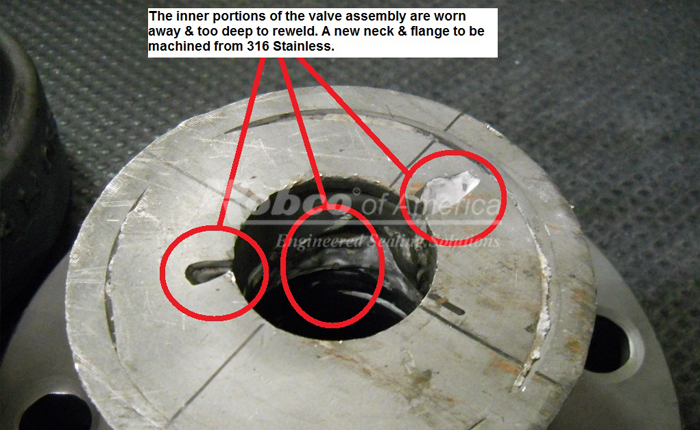

The valve had two welds, one between the neck and body and another between the neck and end flange. We informed the customer that the best solution would be to cut off the old neck and flange and we would machine a new neck and flange from one piece of 316 Stainless Steel thus eliminating one weld set up. This valve assembly also incorporates a SILICON CARBIDE wear bushing inside the neck bore. After looking at the original SILICON CARBIDE bushing Robco of America informed the end user that we could improve upon the original design by increasing the radial wall thickness of this wear bushing. The increased thickness will increase the production run cycles of this valve assembly. The end user informed Robco that they are extremely satisfied with the repair job and will be sending there other valve assemblies over to our repair facility for the same overhaul when required.

Work Rendered for Valve Overhaul