EV03 DOUBLE CARTRIDGE SEAL

A factory assembled, pressure tested, double cartridge seal suitable for pumps, agitators and mixers. Utilizes a barrier fluid to prevent leakage of toxic, hazardous and corrosive fluids to atmosphere.

Features and Benefits

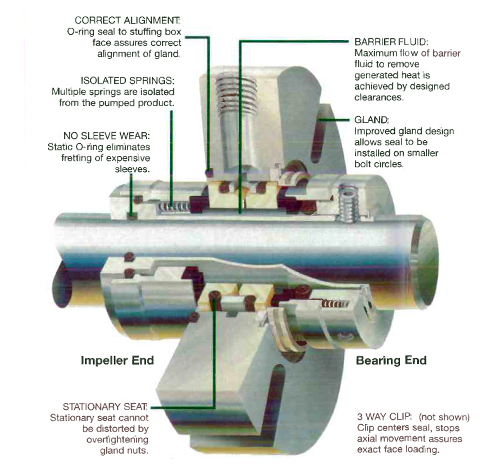

- EASY TO INSTALL – No measuring is required to install the Enviro III cartridge seal.

- NO SHAFT OR SLEEVE WEAR – There are no dynamic “O” rings on the shaft to cause fretting to your equipment and the seal is designed so that all wear parts are disposable.

- ALIGNMENT – Stationary seats are resiliently mounted on an “O” ring and allowed to float for maximum face squareness.

- IMPELLER ADJUSTMENT PUMPS – The Enviro III can be installed on pumps requiring an impeller adjustment after the seal is installed. Adjustments can be made without removing the seal or dismantling the pump.

- NO MODIFICATION TO EQUIPMENT – The Enviro III low profile seal fits all ANSI pumps without modification and is superior in dimensional specifications to any other single cartridge seal commercially available.

- API – Given pump information the Enviro II can be manufactured to meet the American Petroleum Institute specifications for many petrochemical services.

- 3 WAY CLIPS – A clip design that not only centers seal but stops axial movement in both directions.

- “OFF THE SHELF” AVAILABILITY – The Enviro II seal is available in 1.00″ to 3 3/4″. Larger shaft diameters are available on request.

- PRESSURE TESTED – All Enviro II seals are pressure tested before leaving our factory.

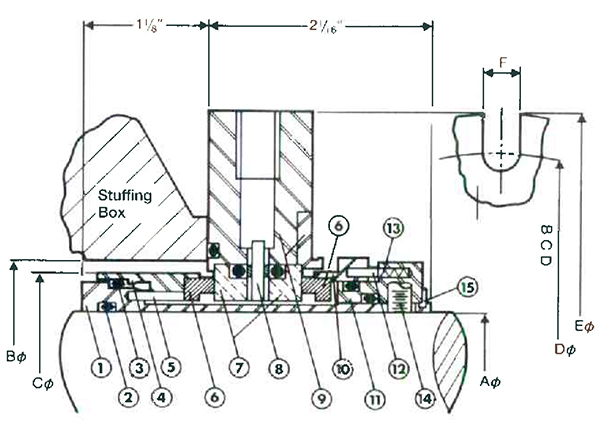

Technical Data and Dimensions

All standard dimensions will be customized to fit your application.

| INCHES | ||||||||

|---|---|---|---|---|---|---|---|---|

| AØ | MIN. BØ | MAX. BØ | C SEAL O.D. | D B.C.D. | EØ | F | ||

| 1 | 1.750 | 1.937 | 1.700 | 2.937 | 4.0 | .562 | ||

| 1 1/8 | 1.750 | 1.937 | 1.700 | 2.937 | 4.0 | .562 | ||

| 1 1/4 | 2.000 | 2.187 | 1.950 | 3.187 | 4.0 | .562 | ||

| 1 3/8 | 2.000 | 2.187 | 1.950 | 3.187 | 4.0 | .562 | ||

| 1 1/2 | 2.250 | 2.437 | 2.181 | 3.437 | 5.0 | .562 | ||

| 1 5/8 | 2.375 | 2.437 | 2.312 | 3.437 | 5.0 | .562 | ||

| 1 3/4 | 2.500 | 2.687 | 2.437 | 3.812 | 5.5 | .562 | ||

| 1 7/8 | 2.625 | 2.812 | 2.562 | 3.937 | 5.5 | .562 | ||

| 2 | 2.750 | 3.000 | 2.687 | 4.062 | 5.5 | .562 | ||

| 2 1/8 | 2.875 | 3.125 | 2.812 | 4.437 | 6.0 | .687 | ||

| 2 1/4 | 3.000 | 3.250 | 2.937 | 4.687 | 6.0 | .687 | ||

| 2 3/8 | 3.125 | 3.375 | 3.062 | 4.687 | 6.0 | .687 | ||

| 2 1/2 | 3.250 | 3.500 | 3.187 | 4.687 | 6.0 | .687 | ||

| 2 5/8 | 3.375 | 3.625 | 3.312 | 4.182 | 6.5 | .687 | ||

| 2 3/4 | 3.712 | 3.950 | 3.650 | 5.687 | 6.5 | .687 | ||

| 2 7/8 | 3.712 | 3.950 | 3.650 | 5.687 | 6.5 | .687 | ||

| 3 | 3.962 | 4.200 | 3.900 | 6.057 | 8.0 | .687 | ||

| 3 1/8 | 3.962 | 4.200 | 3.900 | 6.057 | 8.0 | .687 | ||

| 3 1/4 | 4.212 | 4.550 | 4.150 | 6.307 | 8.0 | .687 | ||

| 3 3/8 | 4.212 | 4.550 | 4.150 | 6.307 | 8.0 | .687 | ||

| 3 1/2 | 4.462 | 4.800 | 4.400 | 6.557 | 8.0 | .687 | ||

| 3 5/8 | 4.462 | 4.800 | 4.400 | 6.557 | 8.0 | .687 | ||

| 3 3/4 | 4.712 | 5.050 | 4.650 | 6.807 | 8.0 | .687 | ||

| 3 7/8 | 4.712 | 5.050 | 4.650 | 6.807 | 8.0 | .687 | ||

| 4 | 4.962 | 5.300 | 4.900 | 6.961 | 8.0 | .687 | ||

SIZES: Metric and sixteenth seals available against specific orders. Larger shaft diameters available against speficic orders.

| MATERIAL SPECIFICATIONS | ||||||||

|---|---|---|---|---|---|---|---|---|

| NO. | STANDARD | SPECIAL | NO. | STANDARD | SPECIAL | |||

| 1 | 316 SS | * | 9 | 316 SS | * | |||

| 2 | Viton | ** | 10 | 316 SS | * | |||

| 3 | Viton | ** | 11 | 316 SS | – | |||

| 4 | 316 SS | * | 12 | 316 SS | * | |||

| 5 | 316 SS | – | 13 | Hastelloy C | – | |||

| 6 | Chemical Grade Carbon | * | 14 | 316 SS | * | |||

| 7 | 99.5% Alumina Ceramic | * | 15 | S. Steel | * | |||

| 8 | 316 SS | * | ||||||

*Consult factory

** EPR, KALREZ, AFLAS, T.V.

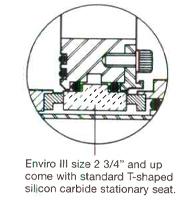

† SIZE 2 3/4″ and above installed with T-shaped seat

– solid silicon carbide as standard.

Aflas is a registered trademark of Asahi Flass Co. Ltd.

Hastelloy is a registered trademark of Cabot Corp.

Viton and Kalrez are registered trademarks of Dupont.

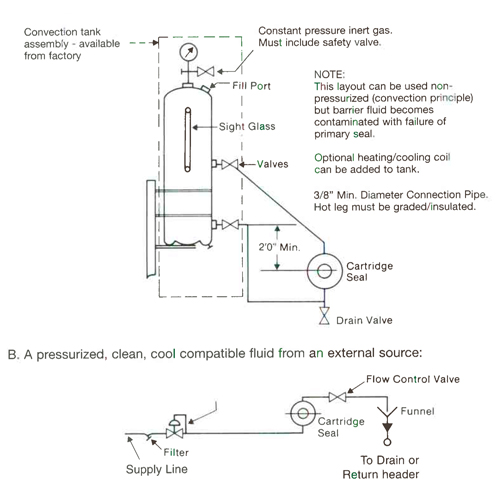

Recommended Seal Environmental Controls

Operating Conditions

Temperature

- Dependent on O-ring compound.

Pressure

- Maximum product pressure 400 psi.

- Maximum barrier fluid pressure 300 psi.

Consult factory for complete specifications.

Note: Set pressure control valve above stuffing box pressure.

Double Balanced

The Enviro III primary seals are balanced when pressurized by the product or the barrier fluid allowing the seal to be used as a double or tandem seal. The barrier fluid can be used to control the media between the seal faces or for environmental control reasons.

Application

STANDBY SEAL: lower barrier fluid pressure idles outboard seal which becomes operational when inboard seal wears out, thus avoiding unscheduled maintenance shutdowns.

PREVENTS CRYSTALLIZATION: temperature in seal area can be maintained at a level where the product will not crystallize by introduction of a controlled temperature barrier fluid.

PREVENTS PRODUCT HARDENING: introduction of barrier fluid excludes air that can cause congealing or hardening of some products.

PREVENTS PRODUCT COOLING: products that become viscous during shutdown can be kept warm by the introduction of a higher temperature barrier fluid.

PREVENTS 0-RING HEAT PRO

BLEMS: a clean, cool, lubricating fluid can be introduced as a barrier fluid to reduce the temperature at the o-rings thus extending seal life.

POSITIVE PRESSURE BARRIER FLUID: introduction of the barrier fluid at 15-25 psi above stuffing box pressure allows the primary seal faces to run on selected media where product is non-lubricating or not in contact with seal (top entering agitators, etc.)

Service

TYPICAL USES: starch, sugar, pulp liquors, brine, pulp stock, caustic, sewage, asphalt, tar, heavy oils, industrial waste, toxic/hazardous chemicals, vapours, gases, liquid ammonia, latex, congealing foods, fruit/vegetable juices, glue, paint, molasses, wine, whiskey, liquors, mine slurries.

For special applications or designs, please contact our factory representative.

Easy to install, no measuring

- Clean stuffing box face, clean and deburr pump shaft or sleeve.

- Lubricate seal sleeve ‘O’ ring with neutral or silicone grease.

- Position seal on the shaft to within 1/4″ of the bearing housing.

- Reassemble remaining pump parts.

- Slide the mechanical seal into position. Tighten all gland bolts, ensuring the gland ‘O’ ring mates with the stuffing box face.

- Tighten all set screws to the shaft or the sleeve.

- Remove all centering & loading clips.

- Connect and pressurize flush.

Total Warranty

All Robco seals are manufactured to exact standards, and are guaranteed free of defects in materials and workmanship. All seals are guaranteed for 90 days from delivery, excepting negligence, misuse and abuse, and will deliver at our expense a new seal to replace any seal found to be defective within said period. No registration card is required.

The warranty is expressly in lieu al all warranties, expressed or implied, and of all obligation or liabilities on our part, including any liability for incidental or consequential damages.

Disclaimer

The temperature limits, pH ranges, pressure ratings, feet per box and shaft speeds shown throughout this pamphlet are representative; the service life and performance of these products can be affected by elevated temperatures and other operating conditions such as chemical resistance, shaft speeds, pressure and equipment in which that the product is being installed. The ratings supplied are suggested as a guideline and should only be used for evaluating your specific application. When in doubt, contact Robco or your ENVIROPAK distributor. The information contained in the pamphlet should not be considered to be a warranty, expressed or implied, including, but not limited to, a warranty of merchantability or fitness for a particular purpose. In no event shall Robco be liable for any incidental or consequential damages resulting from the use, misuse or inability to use the products. This exclusion applies regardless of whether such damages are sought based on breach of warranty, breach of contract, negligence, strict liability in tort, or any other legal theory.

All Robco mechanical seals are manufactured, assembled and tested in America.