ev07 Double Cartridge Outside mounted.

Features and Benefits

- Springs are isolated from pumped product to eliminate clogging.

- Requires no stuffing box.

- Engineered to withstand extreme shaft runout.

- Stationary seal design removes vast vibration/harmonic problems.

- Cartridge designed for easy installation.

- Pressure tested for assurance before leaving Robco’s facility.

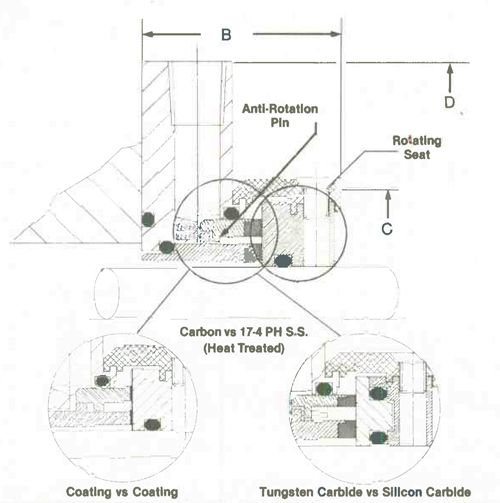

Technical Data and Dimensions

All standard dimensions will be customized to fit your application.

| INCHES | ||||||||

|---|---|---|---|---|---|---|---|---|

| CODE SIZE | SHAFT SIZE | SEAL OUTBOARD DISTANCE | ROTARY SEAT OUTBOARD DISTANCE | GLAND OUTBOARD DITANCE | .375 BOLT | .500 BOLT | .625 BOLT | |

| B | C | D | Bolt Circle | Bolt Circle | Bolt Circle | |||

| 008 | 0.500 | 1.875 | 1.750 | 4.000 | 2.500 | 2.750 | ||

| 010 | 0.625 | 1.875 | 1.875 | 4.000 | 2.625 | 2.875 | ||

| 012 | 0.750 | 1.875 | 2.000 | 4.000 | 2.750 | 3.000 | ||

| 014 | .0875 | 1.875 | 2.125 | 4.000 | 2.875 | 3.125 | ||

| 016 | 1.000 | 1.875 | 2.250 | 5.000 | 3.000 | 3.250 | ||

| 018 | 1.125 | 1.875 | 2.675 | 5.000 | 3.125 | 3.375 | ||

| 020 | 1.250 | 1.875 | 2.500 | 5.000 | 3.250 | 3.500 | ||

| 022 | 1.375 | 1.875 | 2.625 | 5.500 | 3.375 | 3.625 | ||

| 024 | 1.500 | 1.875 | 2.625 | 5.500 | 3.375 | 3.625 | ||

| 026 | 1.625 | 1.875 | 2.875 | 5.500 | 3.625 | 3.875 | ||

| 028 | 1.750 | 1.875 | 3.000 | 6.000 | 3.750 | 4.000 | ||

| 030 | 1.875 | 1.875 | 3.125 | 6.000 | 3.875 | 4.125 | ||

| 032 | 2.000 | 1.875 | 3.250 | 6.000 | 4.000 | 4.250 | ||

| 034 | 2.125 | 1.875 | 3.375 | 6.500 | 4.125 | 4.250 | 4.500 | |

| 036 | 2.250 | 1.875 | 3.500 | 6.500 | 4.250 | 4.500 | 4.750 | |

| 038 | 2.375 | 1.875 | 3.625 | 6.500 | 4.375 | 4.625 | 4.875 | |

| 040 | 2.500 | 1.875 | 3.750 | 6.500 | 4.500 | 4.750 | 5.000 | |

| 042 | 2.625 | 1.875 | 3.875 | 7.000 | 4.625 | 4.875 | 5.125 | |

| 044 | 2.750 | 1.875 | 4.000 | 7.000 | 4.750 | 5.000 | 5.250 | |

| 046 | 2.875 | 1.875 | 4.125 | 7.000 | 4.875 | 5.125 | 5.375 | |

| 048 | 3.000 | 2.156 | 4.250 | 8.000 | 5.000 | 5.250 | 5.500 | |

| 050 | 3.125 | 2.156 | 4.375 | 8.000 | 5.125 | 5.375 | 5.625 | |

| 052 | 3.250 | 2.156 | 4.500 | 8.500 | 5.250 | 5.500 | 5.750 | |

| 054 | 3.375 | 2.156 | 4.625 | 8.500 | 5.375 | 5.625 | 85.875 | |

| 056 | 3.500 | 2.156 | 4.750 | 9.000 | 5.500 | 5.570 | 6.000 | |

| 058 | 3.625 | 2.156 | 4.875 | 9.000 | 5.625 | 5.875 | 6.125 | |

| 060 | 3.750 | 2.156 | 5.000 | 9.500 | 5.750 | 6.000 | 6.250 | |

| 062 | 3.875 | 2.156 | 5.125 | 9.500 | 5.875 | 6.125 | 6.375 | |

| 064 | 4.000 | 2.156 | 5.250 | 10.000 | 6.000 | 6.250 | 6.500 | |

| 066 | 4.125 | 2.156 | 5.375 | 10.000 | 6.125 | 6.375 | 6.625 | |

| 068 | 4.250 | 2.156 | 5.500 | 10.500 | 6.250 | 6.500 | 6.750 | |

| 070 | 4.375 | 2.156 | 5.625 | 10.500 | 6.375 | 6.625 | 6.875 | |

| 072 | 4.500 | 2.156 | 5.750 | 11.00 | 6.500 | 6.750 | 7.000 | |

| 074 | 4.625 | 2.156 | 5.875 | 11.000 | 6.625 | 6.875 | 7.125 | |

| 076 | 4.750 | 2.156 | 6.000 | 11.500 | 6.750 | 7.000 | 7.250 | |

| 078 | 4.875 | 2.156 | 6.125 | 11.500 | 6.875 | 7.125 | 7.375 | |

SIZES: Metric and sixteenth seals available against specific orders. Larger shaft diameters available against speficic orders.

Operating Specifications

Temperature limit:

-40 C to 205 C

-40 F to 400 C

Temperature limit is based on standard elastomer.

Pressure limit to: Vacuum to 17.01 kPA (250 psi)

Shaft speeds to: 3,600 rpm

Standard Material Construction

Metal Components: 316SS

Stationary

Face: Chemical Grade Carbide

Optional: Chrome Oxide Coating, Tungsten Carbide

Rotating

Seat: 17.4 PH SS (Heat Treated)

Optional: Chrome Oxide Coating, Silicon Carbide

Total Warranty

All Robco seals are manufactured to exact standards, and are guaranteed free of defects in materials and workmanship. All seals are guaranteed for 90 days from delivery, excepting negligence, misuse and abuse, and will deliver at our expense a new seal to replace any seal found to be defective within said period. No registration card is required.

The warranty is expressly in lieu al all warranties, expressed or implied, and of all obligation or liabilities on our part, including any liability for incidental or consequential damages.

Disclaimer

The temperature limits, pH ranges, pressure ratings, feet per box and shaft speeds shown throughout this pamphlet are representative; the service life and performance of these products can be affected by elevated temperatures and other operating conditions such as chemical resistance, shaft speeds, pressure and equipment in which that the product is being installed. The ratings supplied are suggested as a guideline and should only be used for evaluating your specific application. When in doubt, contact Robco or your ENVIROPAK distributor. The information contained in the pamphlet should not be considered to be a warranty, expressed or implied, including, but not limited to, a warranty of merchantability or fitness for a particular purpose. In no event shall Robco be liable for any incidental or consequential damages resulting from the use, misuse or inability to use the products. This exclusion applies regardless of whether such damages are sought based on breach of warranty, breach of contract, negligence, strict liability in tort, or any other legal theory.

All Robco mechanical seals are manufactured, assembled and tested in America.