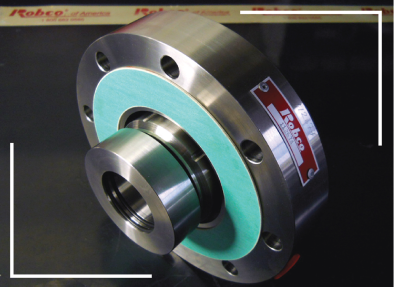

Using a cartridge-type mechanical seal simplifies installation by providing seal components pre-assembled, reducing the chance of installation mistakes.

Using a cartridge-type mechanical seal simplifies installation by providing seal components pre-assembled, reducing the chance of installation mistakes.