The Role of Carbon Graphite Yarn Packing in Sealing Solutions

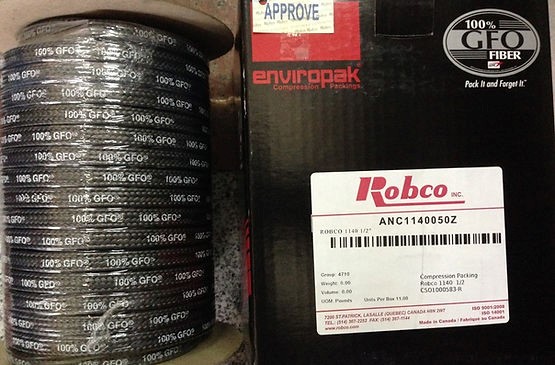

In the world of industrial equipment, ensuring that pumps, valves, and other components are sealed effectively is crucial. One of the unsung heroes in this realm is carbon graphite yarn packing. At Robco of America, we know how vital it is to use the right materials to keep everything running smoothly and safely. What is […]

The Role of Carbon Graphite Yarn Packing in Sealing Solutions Read More »