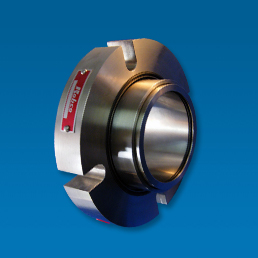

Achieving Efficiency and Reliability with Assembly Style Mechanical Seals

In the world of industrial applications, where efficiency and reliability are paramount, choosing the right mechanical seals can make all the difference. At Robco of America, we understand the critical role that assembly-style mechanical seals play in ensuring smooth operations across a variety of demanding environments. With our comprehensive selection of standard and custom-designed assembly-style …

Achieving Efficiency and Reliability with Assembly Style Mechanical Seals Read More »