If there’s one thing that most centrifugal pumps rely on, it’s the different mechanical seal types manufacturers and operation managers choose to install them. Mechanical seals perform the essential function of preserving pump integrity by eliminating the risk of fluid leaks and chemical contamination. As a result, industrial pumps last longer and don’t require expensive maintenance or frequent replacements.

However, the key to finding the right mechanical seals for effective environmental control and leak prevention is knowing the difference between various mechanical seal types. This will allow you to choose mechanical seals that are highly compatible with your industrial machinery.

While there are several mechanical seal types to meet multiple industrial requirements, here are three of them explained.

Cartridge Mechanical Seal

One of the most common mechanical seal types is the cartridge seal. These are mechanical seals with all the essential seal components preassembled for instant installation. They usually come in an enclosed form that industries can benefit from when trying to save the time and costs associated with assembling a wide range of mechanical seal components.

Mechanical seal manufacturers employ hardware like glands and sleeves to preassemble all the elements of a cartridge mechanical seal. You don’t necessarily need a professional engineer for its installation because of how simple and timely it is.

Furthermore, this mechanical seal type significantly reduces the risk of measuring error because all the assemblies in it are based on fixed and accurate settings. This makes your equipment highly functional with maximum security.

Pusher Seal

Another popular mechanical seal type is the pusher seal. These are primarily used for equipment that requires a secondary mechanical seal to function optimally. Pusher seals work by moving along the pump shaft and rotating with the seal faces of the primary mechanical seals.

The ultimate goal for using these mechanical seal types is to prevent equipment wear and avoid shaft misalignment. Their affordability and customizability make them an excellent mechanical seal type for various industries.

Double Seal

Lastly, one mechanical seal type that’s used in the most severe industrial environments is the double seal. Consisting of two sets of mechanical seal faces, these mechanical seals offer dual pressure from each direction and are installed on massive pieces of equipment for optimal functionality.

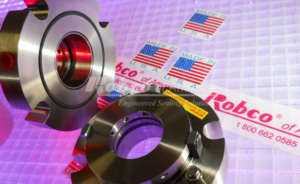

You can now find all these mechanical seal types and more by reaching out to our engineers at Robco of America. From mechanical seal repairs to designing assembly seals for Pumps, we can always help you with our locally manufactured and tested mechanical seals. Contact us at 1-800-662-0585 to learn more today!