The 3 Best Ways to Maintain Your Rotating Equipment

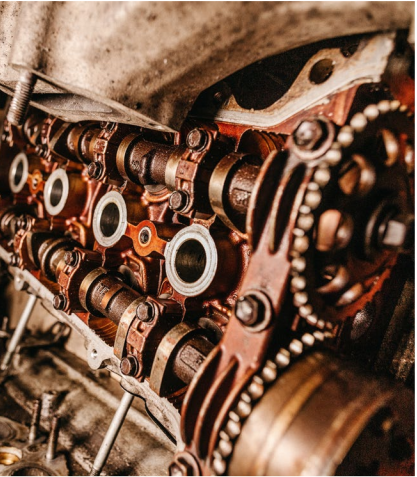

Rotating equipment is an integral part of most industrial operations and manufacturing processes we see today. Whether it’s the textile industry or the pharmaceutical sector, the use of rotating equipment is inevitable these days. The best way to ensure the proper operation of your machinery is to develop a rotating equipment maintenance strategy that can help you […]

The 3 Best Ways to Maintain Your Rotating Equipment Read More »