Rotating equipment is an integral part of most industrial operations and manufacturing processes we see today. Whether it’s the textile industry or the pharmaceutical sector, the use of rotating equipment is inevitable these days. The best way to ensure the proper operation of your machinery is to develop a rotating equipment maintenance strategy that can help you prevent constant repairs and unexpected downtime.

This means doing everything possible to inspect possible causes for defects in the equipment and performing checks that prevent the damage from worsening over time. From testing your machines every once in a while to getting regular mechanical seal repairs, there’s a lot you can do for optimal rotating equipment maintenance.

Here are three of the most effective ways to get started.

Proper Lubrication

The first thing to remember about rotating equipment maintenance is that lubrication is the ultimate secret to its functionality. In other words, rotating equipment is frequently moving. As a result, it always needs lubrication for reduced friction.

Therefore, it’s crucial to focus on the proper lubrication of your equipment with the use of adequate oils and other suitable lubricants. This will ensure the perfect health of your rotating equipment.

Make sure your operational managers frequently check the lubrication of the equipment frequently and re-lubricate it whenever needed.

Check for Unusual Vibration

A significant cause for concern among many manufacturers is the reduced component life in rotating equipment. This often happens when they fail to develop a rotating equipment maintenance strategy that prevents the high vibration levels in the machines.

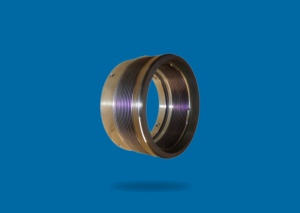

This ultimately affects a wide range of elements involved in the functioning of rotating equipment, including mechanical seals and pump shafts. It’s crucial to balance your rotating equipment using mechanical seals to reduce the high vibration levels during operation.

Use High-Quality Mechanical Seals

Lastly, your choice of mechanical seals plays a significant role in optimal rotating equipment maintenance. This means selecting the right size, shape, and type of mechanical seal and taking all the right steps for proper mechanical seal installation.

You can now meet all the requirements of your gasket solutions Texas by reaching out to us at Robco of America. We’re the ultimate company in the US to help you with a wide range of mechanical seals and mechanical seal repairs whenever needed. Contact us at 1-800-662-0585 to learn more today!