MECHANICAL SEALS CASE STUDIES

Over the past 27 years we have serviced every conceivable type of Mechanical Seal / Mixer Seal / Agitator Seal / Compressor Seal & Reactor Seal. Over this time span we have gained invaluable knowledge in regards to MATERIALS of construction, DESIGN and what makes a MECHANICAL SEAL perform to its full capabilities in all types of industrial applications, including: POWER GEN. / MARINE / CHEMICAL / OIL & GAS / FOOD / PHARMACEUTICAL & MUNICIPAL WATER. Below you will find a cross section of some of the types of mechanical seals we have overhauled over the years. We provide DIGITAL PICS. with our REPAIR QUOTES so our customers get to see and understand what they are paying for. Send us your broken & worn out seals and we will show you the level of SUPPORT & SERVICE we provide to all our customers.

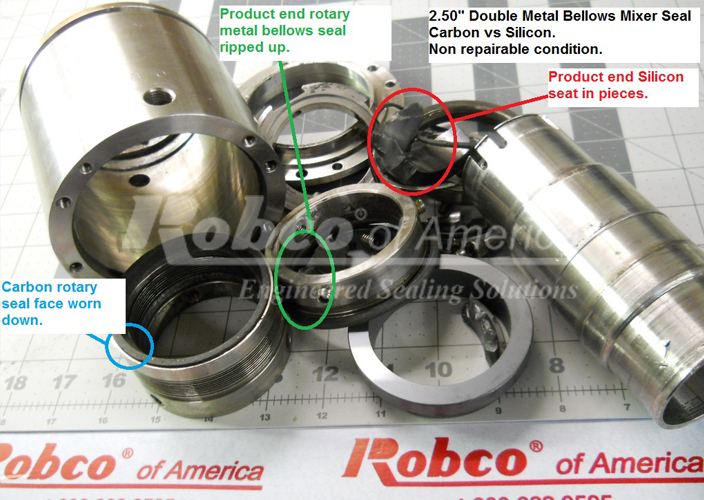

analysis

Overhaul