All types of machines feature moving parts involving rolling or sliding motion. Relative motion examples include linear sliding motion in machine tools or rotation motion in motor vehicle wheels. Machinery moving at very high speeds require bearings – precision-made machine components. They handle stress and help reduce friction in moving parts

On the other hand, the bushing is also a machine component that has a cylindrical shape. It’s an independent plain bearing supporting a shaft. A bushing is similar to a bearing but is a one-part device, unlike a bearing typically made from two or multiple components.

This guide will further discuss the difference between bearing and bushing based on their work and where they’re used.

The Purpose of Bearings and Bushings

Bearings have two main purposes – transmitting forces and motion by guiding and supporting components rotating with one another. The bushing is a type of bearing and its function and performance is based on the material being used. They have an extended service life as well as high durability.

Bearing vs. Bushing – Assembly

Bushings are plain bearings featuring rolling elements like a ball or roller and used to support an assembly. However, bearings allow movement between the machine’s components while providing space between them.

Applications of Bearing and Bushings

Ordinary bearings provide sliding contact while roller and ball bearings give a rolling contact. Bearings are located in vehicles in the steering mechanism, wheels, suspension components, and transmission internal components.

Power turbines, aircraft, pumps, home appliances, and manufacturing machine tools are equipped with bearings. They’re commonly used in low-load, high-precision applications like clocks.

Vehicle suspension systems are one of the most popular applications featuring bushings. Rotary bushings are installed in various machine-related operations requiring precision machine parts.

At Robco of America, our professionals can help you choose between bearing and bushing for an industrial application. We also provide a wide variety of bushings made of different materials.

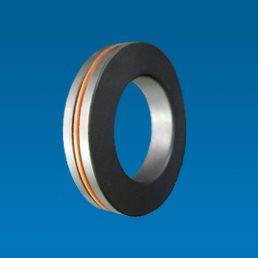

Our technicians are trained to provide quality Engineered Sealing Solutions at affordable rates. They can repair all makes and models of mechanical seals. We also manufacture mechanical seals for industrial pumps, compressors, agitators, mixers, reactors, and bead mill units.

If you’re looking for reliable mechanical seal repair services, call 1-800-662-0585 for technical support or email us at sales@robcoamerica.com. To learn more, check out our website.