3 Beneficial Tips for Purchasing a Mechanical Seal

The manufacturing industry is experiencing a massive boom in various parts of the world. The pressure to manufacture, design, and produce high-quality goods and stay ahead of

Home » Blog

The manufacturing industry is experiencing a massive boom in various parts of the world. The pressure to manufacture, design, and produce high-quality goods and stay ahead of

Mechanical seals are undoubtedly a critical component of industrial machinery and equipment. However, most manufacturers fail to identify where they’re located before repairing or replacing

The most common reason of a pump failure and downtown is mechanical seal leakage. According to research 40% of pump failures in oil refining units

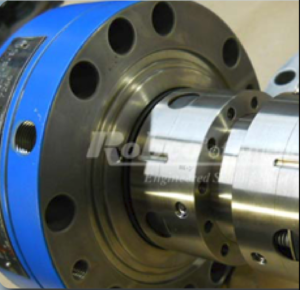

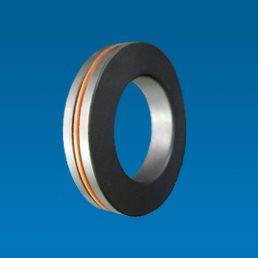

A mechanical seal is used to attach or seal the gap between two or more industrial parts

All types of machines feature moving parts involving rolling or sliding motion. Relative motion examples include linear sliding motion in machine tools or rotation motion

Robco of America, since 1923, has provided excellent alternatives to OEM products along with reliable Fluid Sealing Solutions to U.S.

Toll Free: 800-662-0585

North East: 203-661-3284

Copyright © 2024 Robco of America | Company