Heat effects are a common cause of mechanical seal failure in mixers, agitators, centrifugal pumps, and at every point where a rotating shaft passes through the machine’s housing. Improper seal maintenance, installation, and design often lead to overheating and a major system failure, endangering plant safety and posing an environmental hazard due to pollution from seal leakage. This guide will walk you through the steps that can be implemented to minimize troublesome seal temperature.

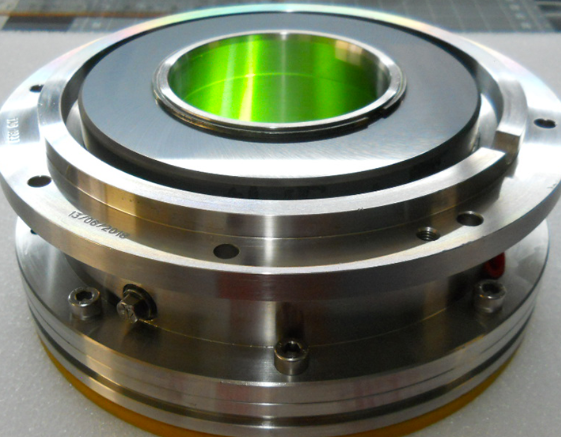

Typical Face Seals

The primary ring in an inside-mounted mechanical face seal is located in the machine while rotating with the shaft. The pressure externally acts from the outer to the inner diameter through the seal face. Inside seals are single seals that are commonly used as they can resist high pressures and even accommodate a variety of flush plans.

The primary ring rotates with the shaft, while the stationary mating ring is fixed with the gland. Either bellows or springs with associated O-rings exert force against the primary ring so that both faces are in contact to prevent leakage. The incoming flush fluid flows across the rings and between the faces to develop a hydrodynamic pressure.

Seal Face Elements

The mating and primary rings are chosen from different materials to minimize wear and friction. These rings are generally selected with materials that have a greater elasticity difference. So, the stiffer face runs into the softer one to provide a tighter seal.

Most seal faces are polished and lapped to obtain flatness. This factor affects the film thickness in the interfacial heat generation and between seal faces.

If the seal temperature is too high, the seal face will blister, crack, and fail. The temperature is affected by factors such as poor surface finish and asperity interactions.

Mechanical Sealing Solutions at Robco of America

Robco of America provides you with the right sealing solution. With proper mechanical seals in place, you can easily deal with temperature changes in your industrial system. We manufacture our own line of cartridge and assembly seals for industrial pumps, mixers, compressors, agitators, and Bead Mill Seal units.

We also offer custom-mechanical seals for various industrial applications and specialize in mechanical seal repair services 24/7.

To learn more, get in touch with us today through our website, or email us at sales@robcoamerica.com.