Dual or double mechanical seals are specifically designed to provide maximum sealing safety. They help eliminate fluid or gas leakage in the mixers of pumps. They offer zero-emission compliance, unlike single seals. These seals are commonly installed in equipment for mixing or pumping toxic or dangerous substances.

They’re essentially required in certain applications, and companies use them to fulfill emission requirements and accomplish environmental goals. A properly installed double seal will control the fluid film on the seal faces and the operating environment.

How Double Seal Works

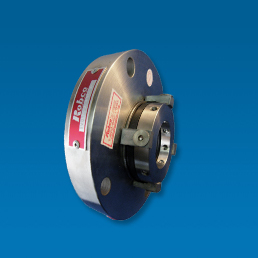

A dual mechanical seal features two primary seals that provide a buffer or fluid barrier space. The primary seal comprises a narrower, softer stationary face accompanied by a wider, harder rotating face. This arrangement leads to wear in the softer seal while the integrity of the hard face seal is maintained during service.

Using Double Seals

Seal and pump manufacturers highly recommend installing double seals for the following reasons:

- Preventing hazardous products from entering the atmosphere and causing pollution

- Avoiding expensive fluid leakage

- Improving seal life by adjusting fluid film

- Isolating mechanical seal from harsh atmospheric conditions

- Providing a suitable alternative when the sealing fluid can’t provide reliable and stable lubrication

- Establishing a backup seal if there’s a planned equipment repair or an inboard seal failure

Controlling the Seal Environment

One way to prolong seal life is to control fluid film on the face of the seal. This provides ideal pressure, temperature, and lubrication. A double seal allows the operator to control these factors.

Dual seals require an exchange of fluids between outboard and inboard seal faces. Each seal features an environmental support system incorporating a buffer or barrier fluid between primary seals.

The fluid flows from a tank to lubricate and cool the seal faces with a piping plan. Pressure and level meters on these tanks are essential for safety and containment.

To choose the most suitable mechanical sealing solutions for pumps, contact professionals at Robco of America. We also offer mechanical seals for various industrial applications and a broad range of mechanical seals for agitators, compressors, reactors, centrifugal pumps, and Bead Mill Seal units.

If you’re looking for reliable mechanical seal repair services, call 1-800-662-0585 for technical support or email us at sales@robcoamerica.com. To learn more, check out our website.