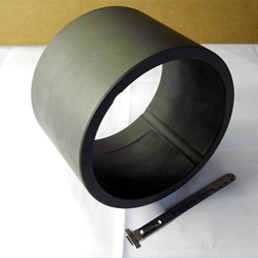

Mechanical seals operate in harsh environments such as high speed, abnormal temperatures, corrosive medium, and high pressure. Silicon carbide is used in mechanical sealing solutions for prolonged seal life, improved performance, and reduced maintenance costs.

Silicon carbide seal faces reduce the likelihood of leakage and failure while protecting the environment from contaminated emissions. They also help reduce energy consumption by lowering friction on shutdown and startup and prevent erosion and wear during an operation.

These mechanical seals are durable while increasing the mean time between failures, leading to lower ownership costs and higher productivity.

High Fluid Pressure

When working under high pressure, a mechanical seal is applied to the face of a bigger load. Since the end compressive stress is greater, the sealing material must have high stiffness and strength.

Silicon carbide offers both qualities, and its elastic modulus is also very high. Moreover, high-end stress will increase heat friction, leading to an increase in temperature. According to experiments, the wear of silicon carbide when paired with carbon graphite is extremely low under several PV values.

High Rotation Speed

For mechanical sealing solutions functioning at high speed, the vibration and wear of friction is the main problem because of the greater linear speed. So the sealing material’s requirements include high strength.

Silicon carbide helps maintain the stability of a seal end face by offering resistance against heat, friction, and wear. A silicon carbide mechanical seal fits the requirements of a high-speed mechanical seal.

Solid Particle Medium

Sealing fluids in an industrial application generally contain solid particles that can be easily deposited on the friction pair’s end. These particles cause severe wear and local heat on the seal face, leading to hot cracks.

Besides offering wear resistance, thermal cracking resistance, and high hardness, silicon carbide has emergency operation properties.

Mechanical Sealing Solutions at Robco of America

Robco of America provides you with the right sealing solution. With silicon carbide mechanical seals in place, you can easily deal with temperature fluctuations in your industrial system. We manufacture our line of cartridge and assembly seals for industrial pumps, mixers, compressors, agitators, centrifugal pump seal parts and bead mill units.

We also offer custom-mechanical seals for various industrial applications and specialize in mechanical seal repair services 24/7.

To learn more, get in touch with us today through our website, or email us at sales@robcoamerica.com.