Bellows are machine components that protect other parts from dirt and dust to extend service life and minimize chances of machine downtime. They also protect machine operators from injuries caused due to contact with movable machine parts.

Bellows are more commonly used in machine designs as they’re ideal for several covering purposes. Moreover, they can adapt to machines of different sizes because of their flexible rods and give an attractive finish.

Typically, bellows are of four types – conical fold bellows, cylindrical fold bellows, rubber disc bellows, and single-fold bellows.

Folded Bellows

These types of bellows are specifically designed to prevent injuries in machine operators. When installed on machines, they minimize contamination of slide-ways by coolant, chips, or dust. Folded bellows are customized according to the machine’s specifications, and a specific production process thermally welds the reinforcing frames to cover the material.

These covers are dimensionally stable and properly sealed to prevent liquid and dust from entering. Common applications of folded bellows include medical engineering, testing and measuring machines, wood-working machines, and water-jet machines.

Conical Rubber Bellows

Conical rubber bellows have a specific cone shape and are effective in various ways. They absorb thermal movements and noise in the machinery and eliminate vibration between components such as water pumps, engines, and condensers.

These bellows compensate for minor installation misalignments, while custom-made conical bellows can seal environmental elements such as sand and dust from the machine’s moving parts.

Rubber Disc Bellows

These high-grade bellows are the most common choice for industrial applications. They can be made without mold cost and serves as an economical solution even for lower quantities. Its relation with L max and L min (the highest and lowest values calculated by the sound meter in a given period) and its availability in various materials offer a technical solution.

With varying disc sizes and collar flange shapes, an unlimited number of variations can be produced. Rubber disc bellows are available in more designs and shapes.

Some of the commonly used applications include measuring machines, mechanical engineering, pistons and spindles, and hydraulic and pneumatic bars.

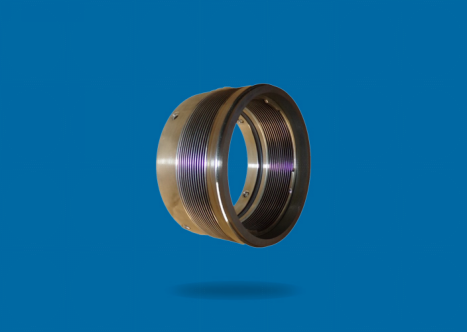

At Robco of America, we provide a wide variety of bellows and manufacture our line of Cartridge Mechanical Seals for industrial pumps, mixers, agitators, reactors, and bead mill units.

For reliable mechanical seal repair services, call 1-800-662-0585 for technical support or email us at sales@robcoamerica.com. To learn more, check out our website.